TangenX® Flat Sheet Membranes

ProStream and HyStream, two modified Polyethersulfone (mPES) membrane chemistries, are used in TangenX® flat sheet cassettes, offering superior selectivity for a wide range of applications.

Compliant

HIGH PERFORMANCE

HIGH PERFORMANCE

Uniform Pore Distribution

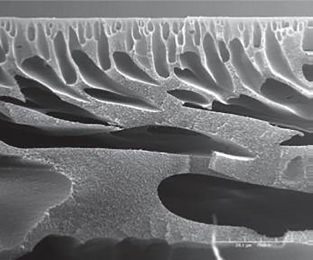

The selective portion of an ultrafiltration membrane is the shiny surface layer known as the “skin” of the membrane. The layer beneath the skin is made up of a “finger pore” structure that supports the skin and facilitates liquid flow.

The scanning electron micrograph image shows uniformity in the finger pores of the TangenX® membrane substructure. This allows for minimal particle entrapment, which results in low fouling and maximum fluid flow. Repligen has developed this membrane substructure to ensure a defect-free surface and to provide maximum adhesion to the substrate while achieving highest possible flow rates.

Porous substructure of the TangenX® ProStream 10K membrane

HIGH PERFORMANCE

HIGH PERFORMANCE

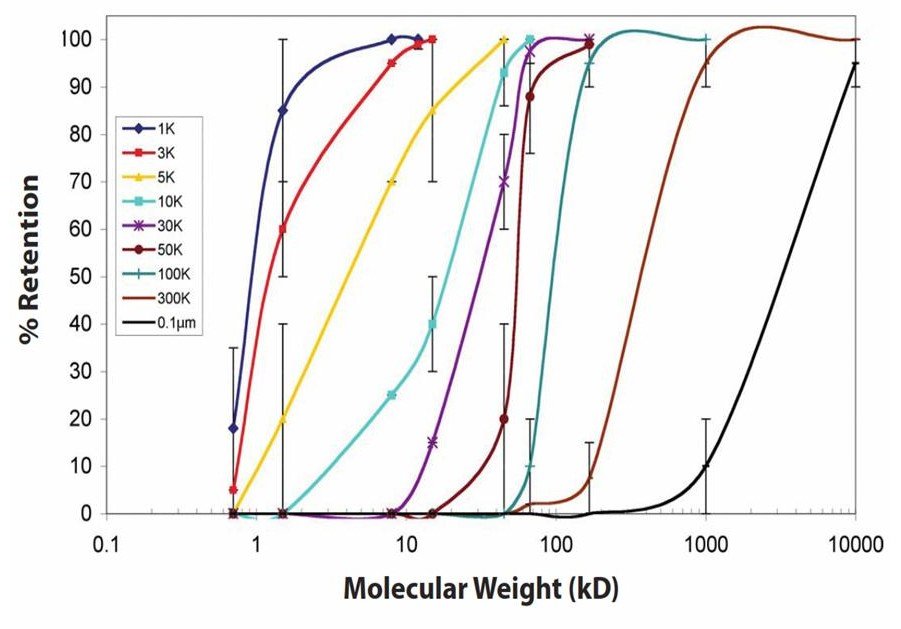

High selectivity

Ultrafiltration membranes utilize nominal Molecular Weight Cut-offs as a measure of the pore size distribution across the membrane surface. The more uniform the pore size, the better the membrane’s selectivity is. A narrow pore size distribution means the membrane has high selectivity; i.e., the membrane has a high ability to differentiate between macromolecules of a more similar size.

The curves shown graphically represent the selectivity profile of several different membrane Molecular Weight Cut-offs offered by Repligen. Each membrane selectivity curve is distinctly separated from one another with no overlap and shows a high degree of selectivity. This leads to higher process performance and product yield.

HIGH PERFORMANCE

HIGH PERFORMANCE

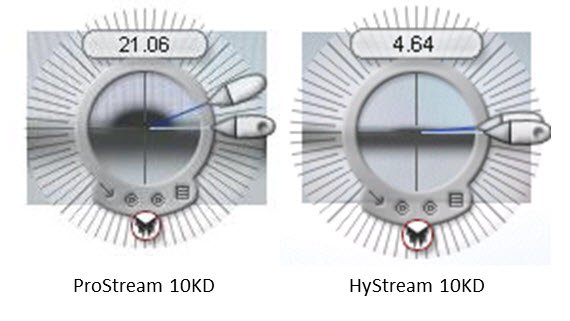

High flux

The graph shows an optimization of transmembrane pressure (TMP) with a 30mg/ml monoclonal antibody feed stream. Under standardized conditions, Repligen's flux rate is highest at any given TMP. This results in greater process efficiency, a reduction in process time, and cost savings.

Source: IBC Applications for Biopharmaceuticals, La Jolla, CA, June 1-3 2009.

COMPLIANT

COMPLIANT

GMP-validated membranes

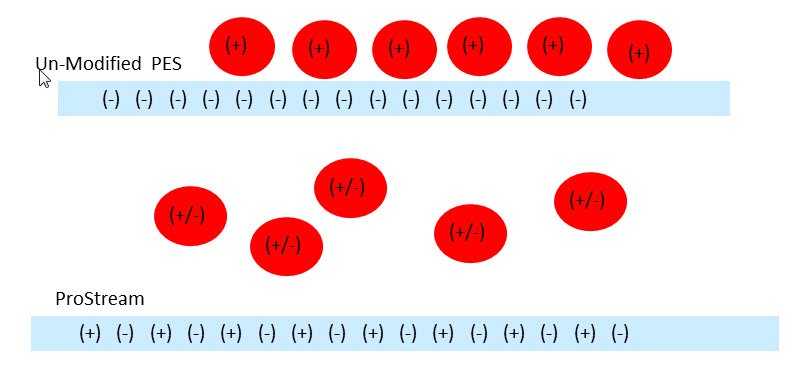

Repligen manufactures two membrane chemistries for use in flat sheet cassettes, ProStream and HyStream, in both ultrafiltration and microfiltration pore sizes. Both are modified Polyethersulfone (mPES) membranes validated for use in cGMP processes. The modification, achieved by the addition of a second polymer into the pre-casting membrane solution, ensures total and consistent surface modification.

ProStream membrane is neutrally charged, rendering it low binding for enhanced flux and recovery. HyStream membrane is extremely hydrophilic in nature, resisting fouling from hydrophobic specied such as fat, lipids, and various antifoam agents.

TangenX® Flat Sheet Membranes

TangenX flat sheet membranes achieve high flux and selectivity using a controlled manufacturing process that enables tight control of the membrane pore size. The process ensures a controlled transition from the selective surface to the microporous support.

Click on the tabs below to explore different features of the TangenX flat sheet membranes.

ProStream membrane is neutrally charged, rendering it low binding for enhanced flux and recovery. The membrane has excellent chemical resistance and very low extractables, with performance comparable to Millipore Biomax, Pall Omega.

- Neutrally balanced charge/Low protein binding

- Ideal for downstream ultrafiltration processes where high product recovery is important

- Modified to minimize protein absorption due to non-specific binding

- Process flux and product yield higher than with unmodified PES membranes

Since it is neutrally charged, ProStream membrane minimizes non-specific protein binding. Unmodified PES has an inherent negative charge and will have non-specific binding.

HyStream membrane is extremely hydrophilic in nature, resisting fouling from hydrophobic species such as fat, lipids, and various antifoam agents. The membrane has good chemical resistance and offers an alternative to RC membranes in some cases, with performance comparable to Millipore Ultracel, and Sartorius Hydrosart.

- Hydrophilic - Minimal fouling by hydrophobic molecules/Low protein binding

- Ideal for upstream and downstream filtration operations where minimal fouling and high flux rates are important

- Prevents the dramatic decrease in flow rate that typically occurs when hydrophobic species are present

Because HyStream membrane is modified to be very hydrophilic, the contact agent is lower than neutrally charged membranes.

Membrane Selection Guide

There are other factors that can influence the selectivity and retentivity of a membrane. The shape of a molecule, presence of other solutes, pressure, adsorption and ionic conditions may affect membrane performance. A Repligen Field Application Specialist can help guide membrane selection for specific applications.The following table shows typical use of flat sheet membrane chemistries by application.

- In general, select a Molecular Weight Cut-off (MWCO) that is 3 to 6 times smaller than the protein or other molecule you want to retain

- If obtaining highest possible flow rates is most critical, select a more open MWCO membrane at the lower end of the range (3X)

- If retention is the main objective, select a tighter MWCO membrane at the upper end of the range (6X)

Membrane Discs

Membrane discs are available using HyStream or ProStream in all porosities. TangenX® membrane cut discs are available in common diameters to fit conventional stirred cells and the TangenX® X-Flo76 membrane screening system. Discs are disposable; however, if appropriate cleaning measures are taken, they may be washed and reused typically 10 to 20 times. Disc sizes are available in 25 to 90 mm.

Below, is the list of membrane disc sizes available. Please specify membrane type and molecular weight cut-off when ordering.

TFF genius

You’re not asking for too much. Combine high selectivity and reduced processing time. Become a TFF genius and get it all with TangenX® Membranes and TFF Devices.

Manufacturing Centers of Excellence

Repligen develops and manufactures products for the biopharmaceutical industry under an ISO 9001 quality management system. We focus on the timely delivery of high quality, consistent and robust products, to ensure business continuity for our customers.

Repligen manufacturing sites are located in Massachusetts, California, and New Jersey in the United States and in Sweden, France, The Netherlands, Germany and Estonia.

Validated Manufacturing

Quality Manufacturing

TangenX® Cassettes are manufactured in a fully validated and documented manufacturing process according to the principles of cGMP. Each cassette comes with a Quality Assurance Certificate.

Comprehensive Regulatory Support Files

Each TangenX® TFF Cassette is supported by a Regulatory Support File (available upon request) that includes:

- Product information

- Cassette design

- Materials of construction

- Product performance

- Safety information

- Documentation system

- Product Manufacturing

- Qualification

- Manufacturing Process Validation

- Release Testing

Customer First.

Support is part of the Repligen DNA. Our goal is to provide exceptional customer experience, and to support the efficient and successful adoption and implementation of all Repligen products and services.

- Field Application Support

- Customer Service

- Field Service Engineers

Membrane Screening Hardware

The X-Flo76 Membrane Screening System utilizes 76 mm membrane discs to determine the most advantageous balance of selectivity and flux.

- Efficient predictable membrane screening

- Representative tangential flow characteristics

- Convenient processing of 15-500 mL

- Quick easy assembly (Area: 30 cm2)