CaptivA® HF Protein A Affinity Resin

The value choice in Protein A resins, CaptivA® HF Resin delivers industry-standard results at a fraction of the cost of traditional affinity resins.

Protein A affinity chromatography for bioprocessing

Protein A affinity chromatography resin is used primarily for the purification of antibodies, particularly immunoglobulin G (IgG) from various biological feedstocks. Protein A, a bacterial protein derived from Staphylococcus aureus, binds specifically to the Fc region of IgG antibodies. This binding property makes Protein A an excellent ligand for affinity chromatography, allowing for the selective capture and purification of antibodies from complex feedstocks.

Key Applications:

- Monoclonal Antibody Purification: Essential in the biotechnology and pharmaceutical industries for the production of therapeutic antibodies

- Polyclonal Antibody Purification: Used in research laboratories for isolating antibodies from serum or other biological feedstocks

- Immunoprecipitation: Enables the isolation of specific proteins or complexes from cell lysates by using antibodies

Benefits:

- High Specificity and Yield: Efficiently captures antibodies, providing high purity and yield

- Scalability: Suitable for both small-scale laboratory research and large-scale commercial manufacturing

- Compatibility: Works with various chromatography systems and can be used in different buffer conditions

Overall, Protein A affinity chromatography resin is a powerful tool in the purification and production of therapeutic antibodies, playing a vital role in both research and clinical applications.

CaptivA® HF Protein A Affinity Resin

CaptivA® HF Protein A Affinity Resin combines an industry standard cross-linked agarose bead with recombinant native Staphylococcal Protein A (rSPA) manufactured by Repligen, the world’s leading manufacturer of recombinant Protein A.

Base Matrix

4% highly cross-linked agarose bead

Particle Size

45-165 μm

Ligand

- Recombinant native Staphylococcus Protein A (rSPA)

- Recombinant form equivalent to the native Protein A form

- Contains all five immunoglobin binding domains (E,D,A,B,C)

- Coupling via reductive amination provides multi-point attachment

Dynamic Binding Capacity

44 mg hIgG/ mL at 6 min residence time

Protein A Leaching

< 10 ng/mg IgG

Caustic Stability

Maintains 80% capacity after 15 hours exposure to 0.1 M NaOH

Recommended Flow Velocity

100-350 cm/h

Recommended pH and Temperature Stability

Working: 3-10

Cleaning-in-Place: 2-13

Temperature Stability: 4-40 C

RELIABLE PERFORMANCE

RELIABLE PERFORMANCE

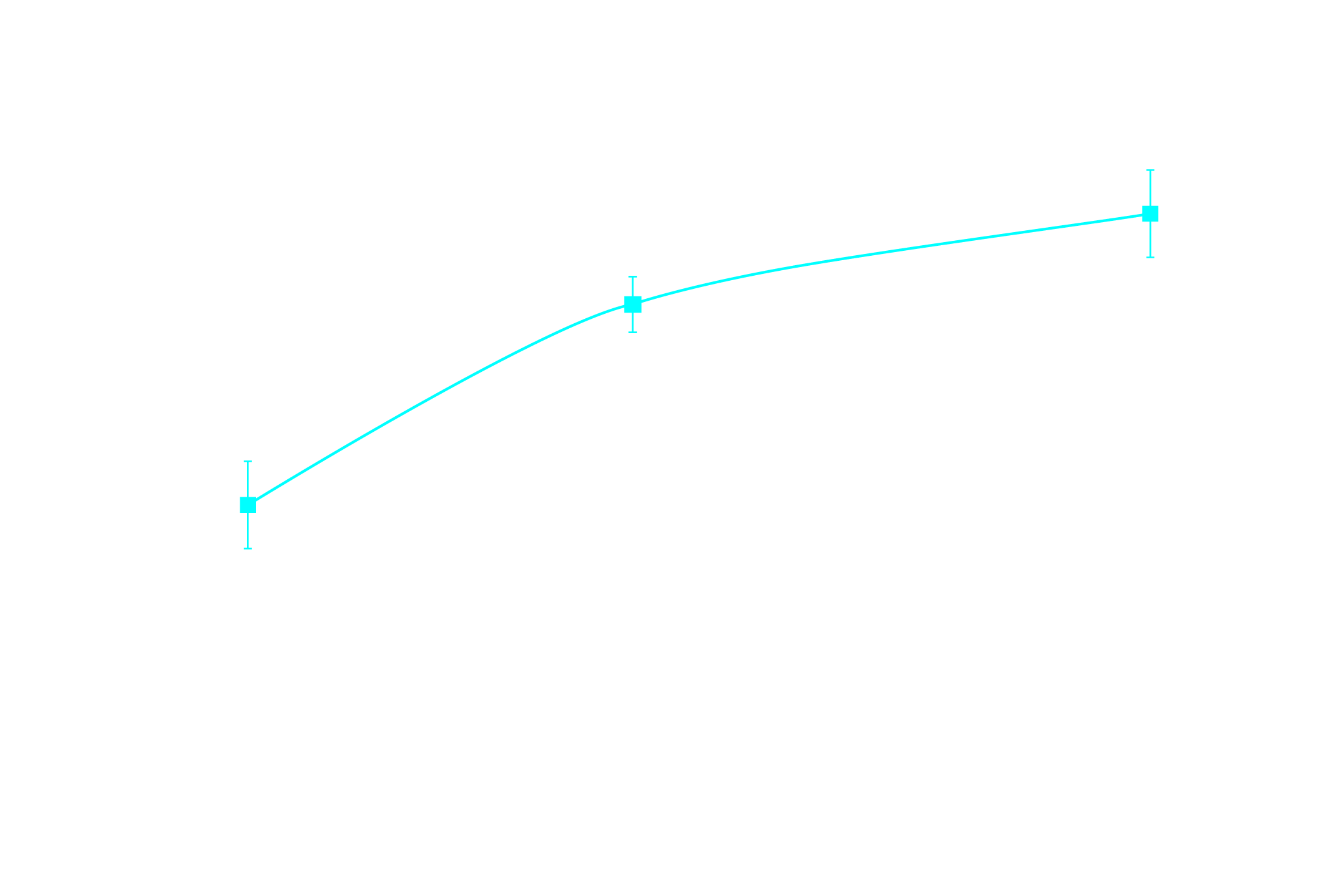

High dynamic binding capacity

CaptivA® HF Protein A Affinity Resin delivers high dynamic binding capacity at standard process flow rates and residence times.

Dynamic binding capacity was determined for human polyclonal IgG at four different flow rates providing residence times ranging from 0.5 to 6 minutes. A 5 x 50 mm column was loaded with a 2 mg/ml hIgG solution in PBS pH 7.4. Capacity was determined and reported at 2, 5, and 10% breakthrough. A column bed height between 10-20 cm, loaded at 200 cm/hr provides 6-12 minutes of residence time.

RELIABLE PERFORMANCE

RELIABLE PERFORMANCE

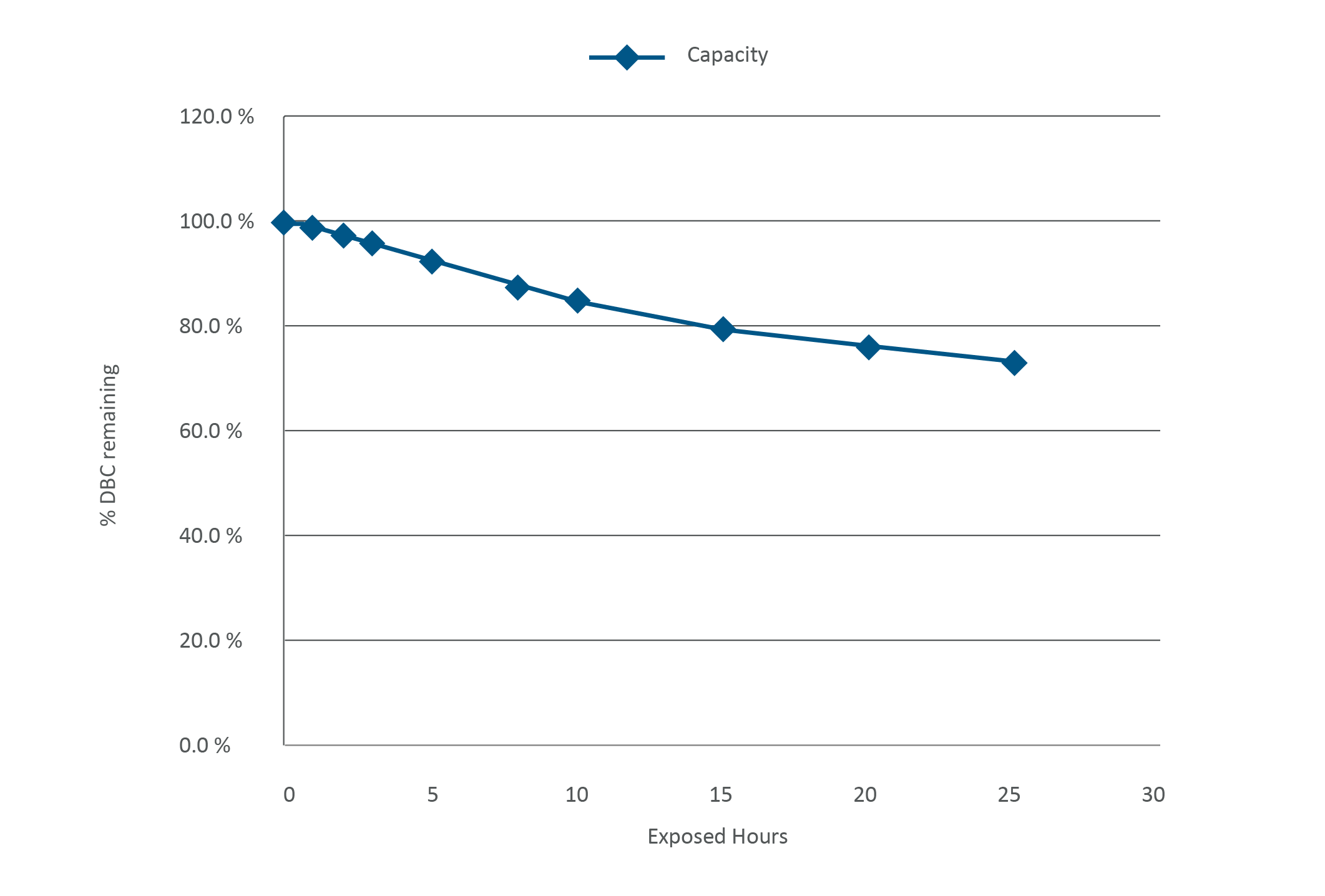

Sanitization stability

CaptivA® HF Protein A Affinity Resin retains desired dynamic binding capacity when exposed to stringent washing conditions that reduce standard feed stream contaminants. The CaptivA® ligand attachment mechanism creates multiple covalent attachment points between the ligand and agarose bead resulting in superior alkali stability compared to single point attachment chemistries.

The dynamic binding capacity was determined for polyclonal human IgG following 0.1 M NaOH exposure at various time points. 80% of the initial capacity is maintained through 15 hours of exposure to 0.1 M NaOH.

RELIABLE PERFORMANCE

RELIABLE PERFORMANCE

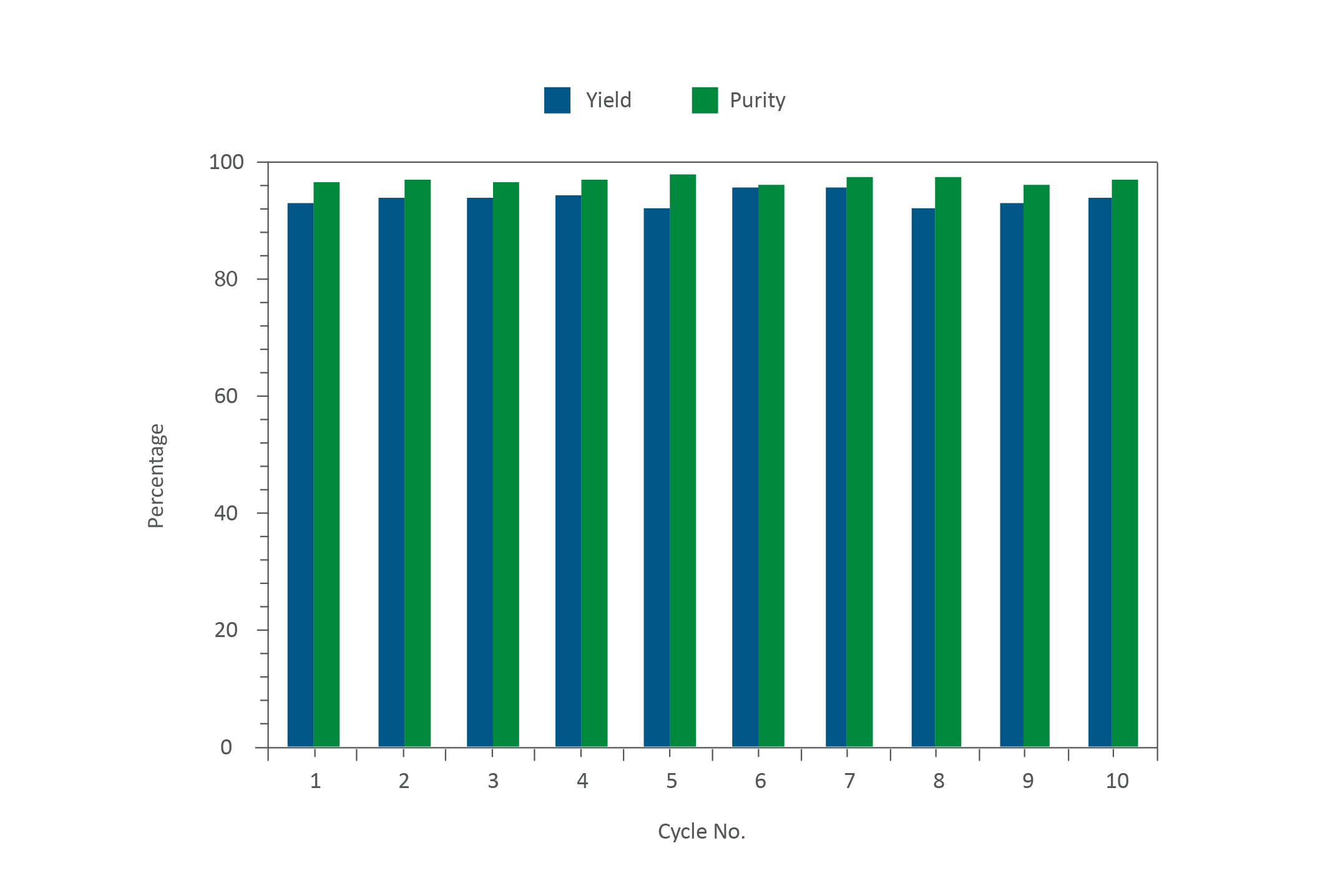

Low protein A ligand leaching

CaptivA® HF Protein A Affinity Resin multi-point protein chemistry consistently delivers low Protein A ligand leaching.

The human polyclonal IgG yield and purity were determined following each of 10 column cycles by Roche Cedex Bio and SEC-HPLC, respectively. Resin was cleaned using 5 column volumes of 0.1 M NaOH between cycles. Leached ligand was determined across 10 column cycles by measuring protein A in product elution pools using the Repligen Protein A ELISA Kit.

RELIABLE PERFORMANCE

RELIABLE PERFORMANCE

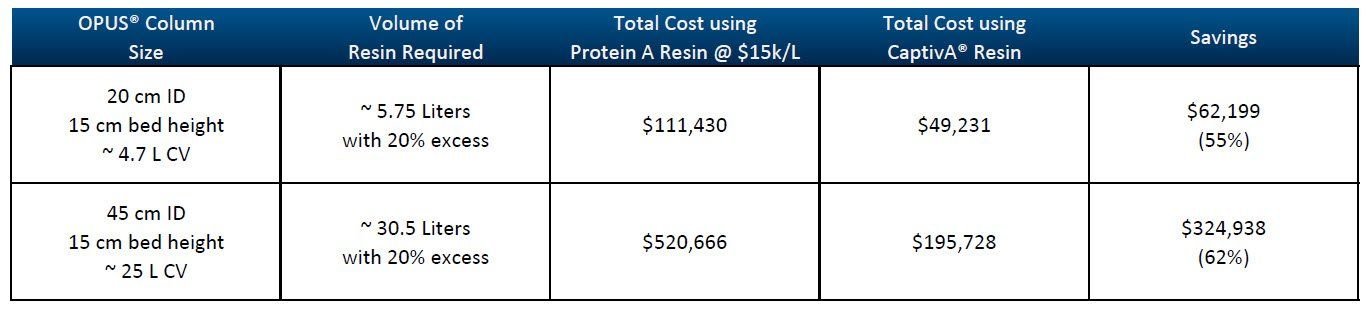

High cost-efficiency

CaptivA® HF Protein A Affinity Resin is the most cost-effective chromatography resin available today, delivering industry standard performance at a fraction of the cost of traditional affinity resins, especially when pre-packed into OPUS® chromatography columns.

MANUFACTURING EXCELLENCE

MANUFACTURING EXCELLENCE

Available pre-packed in OPUS® Columns for quick deployment

OPUS® pre-packed chromatography columns offer a streamlined and efficient solution for process development, process validation, and clinical and commercial manufacturing. Designed for reliability and performance, these columns come pre-packed with your specified chromatography resin, eliminating the need for time-consuming and labor-intensive packing processes. OPUS columns ensure consistent and reproducible results, which are critical for validating processes and meeting regulatory standards. Their robust construction and scalability make them ideal for transitioning from clinical trials to full-scale commercial manufacturing volumes. By integrating OPUS pre-packed columns into your workflow, you can enhance process efficiency, reduce downtime, and achieve faster time-to-market for your biopharmaceutical products.

Manufacturing Centers of Excellence

Repligen develops and manufactures products for the biopharmaceutical industry under an ISO 9001 quality management system. We focus on the timely delivery of high quality, consistent and robust products, to ensure business continuity for our customers.

Repligen manufacturing sites are located in Massachusetts, California, and New Jersey in the United States and in Sweden, France, The Netherlands, Germany and Estonia.

Customer First.

Support is part of the Repligen DNA. Our goal is to provide exceptional customer experience, and to support the efficient and successful adoption and implementation of all Repligen products and services.

- Field Application Support

- Customer Service

- Field Service Engineers