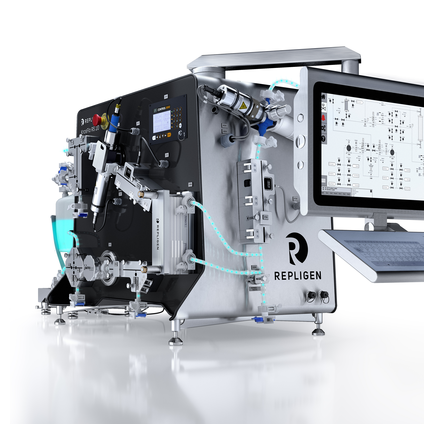

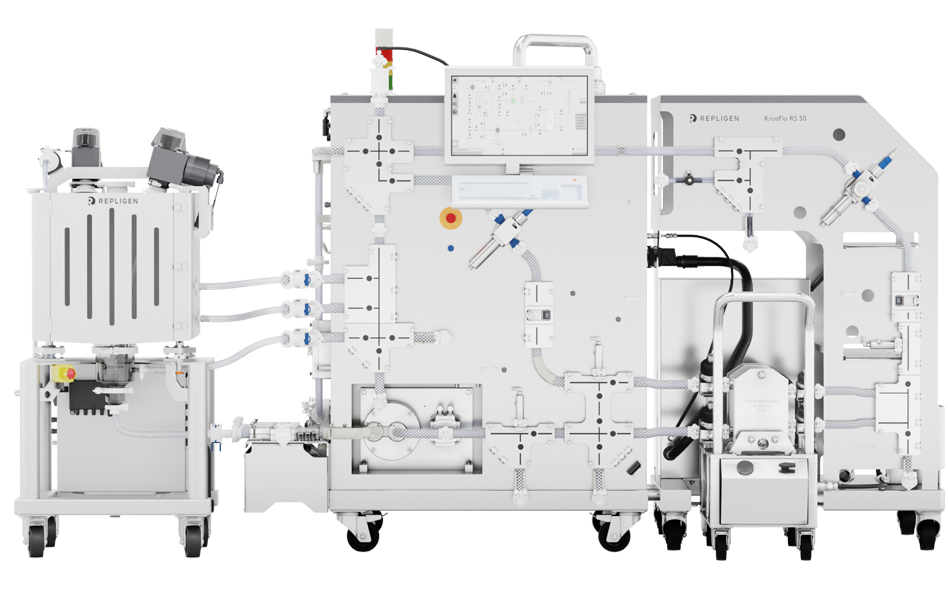

KrosFlo® RS TFF Systems

The KrosFlo® RS are a series of tangential flow filtration (TFF) systems engineered for an era of new modalities. These systems are single-use and cGMP compliant with features like end-to-end automation, minimal hold-up volumes, and effortless scalability. Support automated ultrafiltration and diafiltration (UF/DF) processes for batch volume ranges of 35mL to 2000L.

WHEN EVERY DROP COUNTS

Minimize hold-up volumes and reduce batch variation with valve block technology and end-to-end automation.

ENHANCED PROCESS CONTROL

Experience intelligent mixing and recipe customization with Tulip tank and intuitive recipe-driven software platform.

SCALABLE SOLUTION

Scale effortlessly from 1/8” to 1” while maintaining process parameters.

Bench scale TFF meets cGMP production

Bench scale TFF meets cGMP production

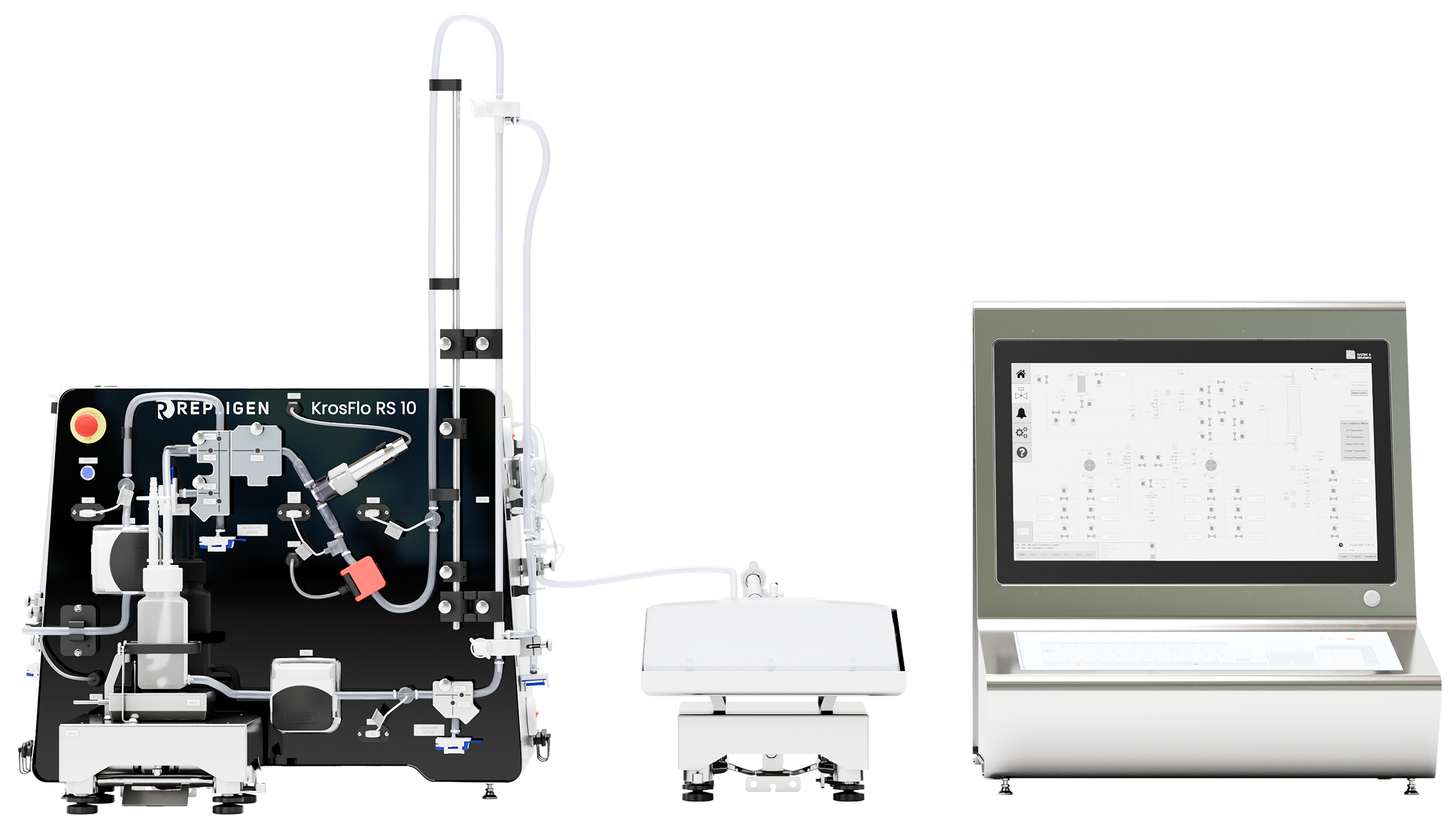

Introducing the KrosFlo® RS 10

Meet the first bench scale TFF system built specifically for cGMP production with true end to end automation.

The new KrosFlo RS 10 takes all of the components, controls, and capabilities of our highly compliant, commercial manufacturing large-scale TFF systems and brings it down to bench scale.

One feature unique to the RS 10 is the ability to choose your own feed pump upon ordering to better fit your process needs.

- Centrifugal

- Diaphragm

- Peristaltic

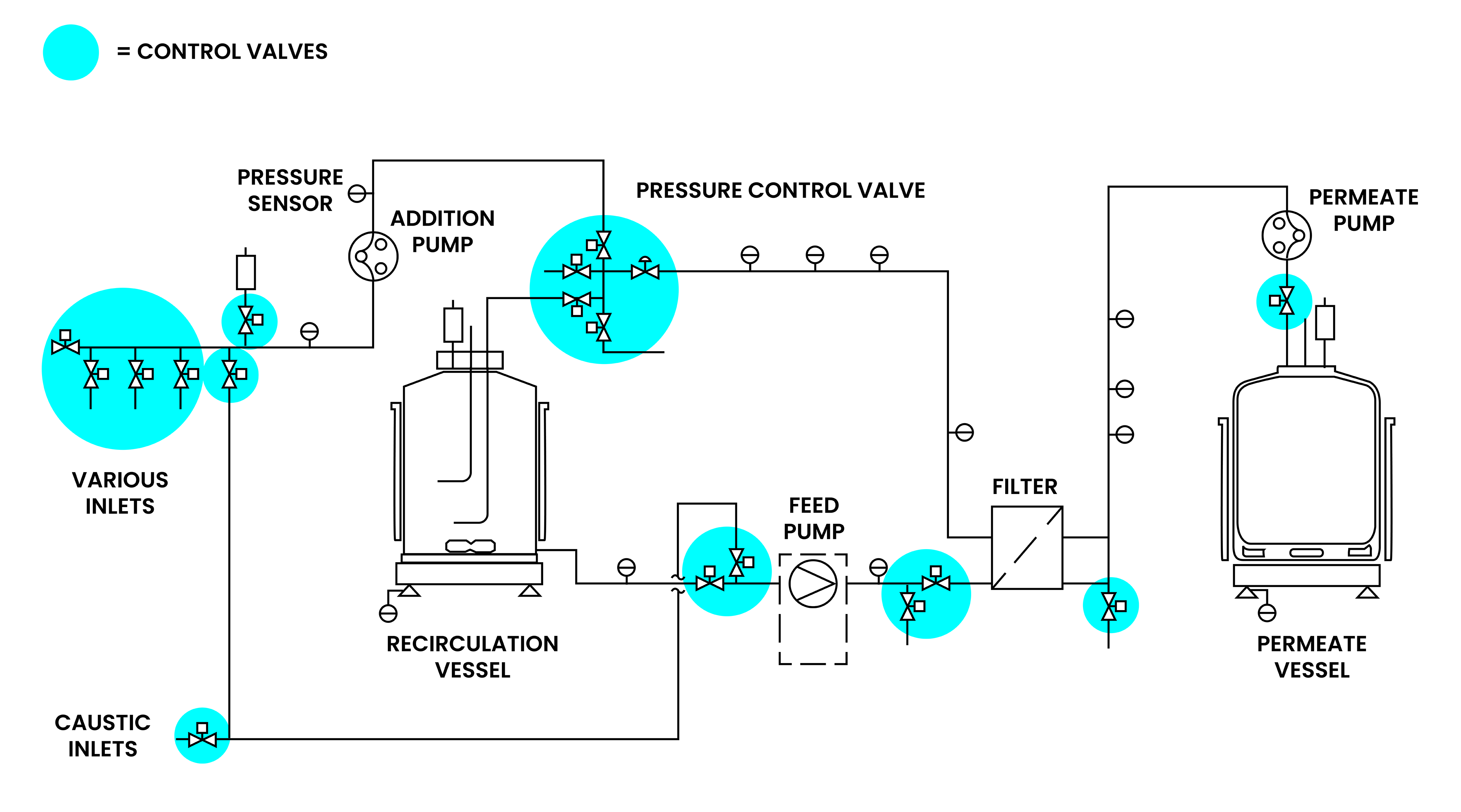

Automation Redefined

While many traditional single-use TFF systems claim to be “automated” they often require frequent manual intervention by operators due to the limited number of controlled valves available. The more controlled valves throughout the system’s flow path, the greater the degree of automation capability.

With significantly more controlled valves than any other TFF systems on the market, the KrosFlo® RS enables users to truly automate the entire process, end-to-end, significantly reducing the risk of human error and inconsistencies from batch-to-batch. Automation beyond UF/DF- that’s end-to-end.

- WFI/Buffer Flushing

- Integrity testing

- Fed-Batch Concentration

- Product Recovery

- Clean-in place

- NBP testing

Recovery Maximized

Traditional hose barb assemblies found on most TFF system flow-paths space valves far apart increasing total hold-up volume and creating dead-legs which limits concentration capabilities. The ProConnex® flow paths featured on KrosFlo® RS are made up of injection molded tubing connections that fit precisely within the recesses of the system’s valve blocks.

The valve block technology allows the RS to cluster a set of valves close together for automated and optimized concentration.

These features and more make these the TFF system of choice for mRNA and gene therapy manufacturers.

Full Process Control Unlocked with KlariFi™

The RS series is powered by the KlariFi™ system control software, an intuitive recipe-driven platform that unlocks the full potential of your TFF run. Use the point and click recipe editor to build from scratch or to customize from an extensive library of pre-built templates.

Enjoy ease of navigation with a flow diagram-based interface that mirrors your system’s hardware. Process controls, settings, and data are available at a glance with the ability to visualize, pause and adjust during a run without compromising batch integrity. Best of all, KlariFi™ is built to enable CFR 21 part 11 and GAMP 5 compliance.

- Intuitive point and click interface

- Windows-integrated access control

- Transfer recipes between systems

- Secure batch reports

- Customizable data trending

Intelligent Mixing Even at the Lowest Working Volume

Innovative tulip tank technology delivers hold-up volumes as low as 1.5L with active mixing.

As fluid levels drop, the dual impellers independently adjust speed to reduce harmful surface interaction while automated valves adapt retentate flow to avoid damage upon entering the tank.

Tulip Tank cart available with KrosFlo® RS 30, 40, 50

Filter Flexibility

Expand your application usage by using the KrosFlo® RS with flat sheet cassettes or hollow fiber filters. Swap between filter types in less than 10 minutes.

Repligen offers the broadest range of membrane formats in the market with TangenX® Cassettes and Spectrum® Hollow Fiber filters.

KrosFlo RS TFF System Overview Videos

New to the KrosFlo RS Systems? Get access to immersive overviews and tutorials with TFF experts using live equipment.

KrosFlo RS 10 TFF System Overview

Join Lucas Smith as he highlights Repligen’s latest innovation in bench-scale TFF technology, the KrosFlo® RS 10 TFF system. Designed to streamline cGMP manufacturing for small batch therapeutics, the KrosFlo® RS 10 enables operators to choose their preferred feed pump, automate all process steps, and maximize yields. In this overview video Lucas will discuss system features, process flow, and network integration capabilities.

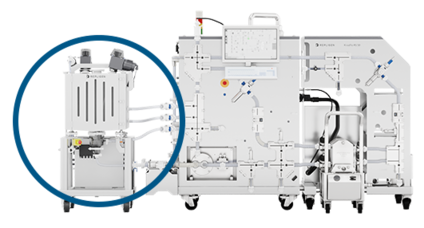

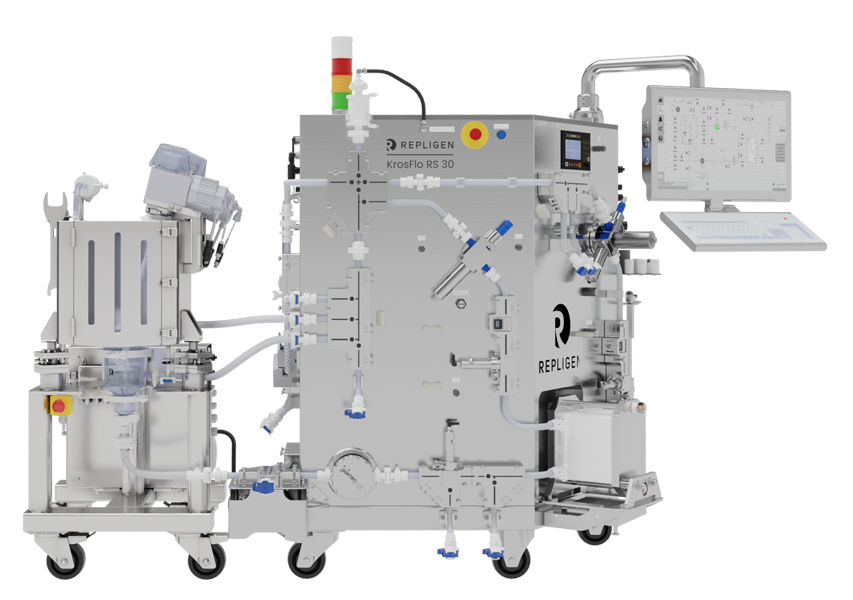

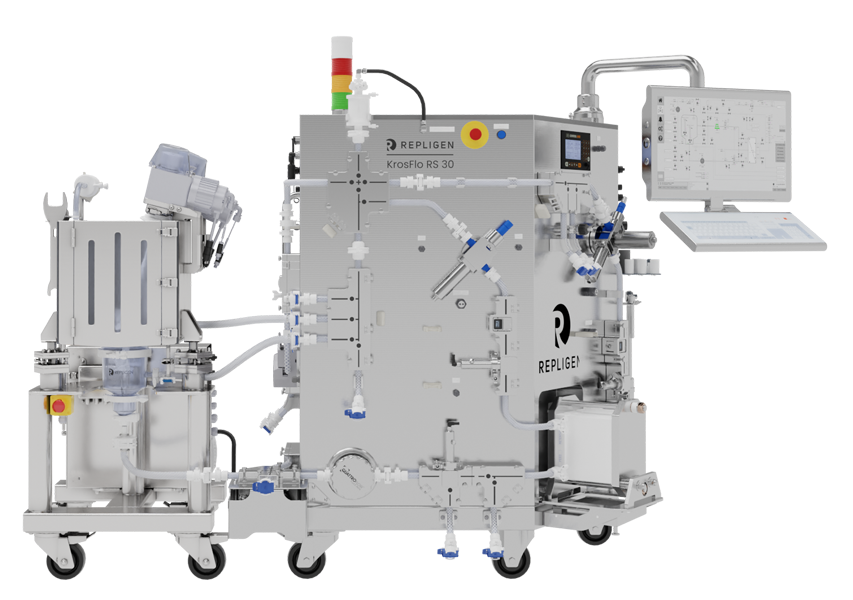

KrosFlo RS 30 TFF System Overview

In this video Lucas Smith walks you through the KrosFlo RS® 30 TFF System, Repligen’s integrated solution to empower cGMP manufacturers with end-to-end automation and optional real-time concentration control. The system comes with 1/2” line sizes, a membrane area ranging between 1 and 5 m2 and is designed to provide you with everything needed for cGMP compliance.

ProConnex Flow Path Installation on KrosFlo RS 30 TFF System

Intuitive and done in a matter of minutes, Lucas Smith provides a step-by-step installation of the ProConnex® flow path onto the KrosFlo® RS 30. The process outlined in this brief overview is applicable to all KrosFlo RS systems.

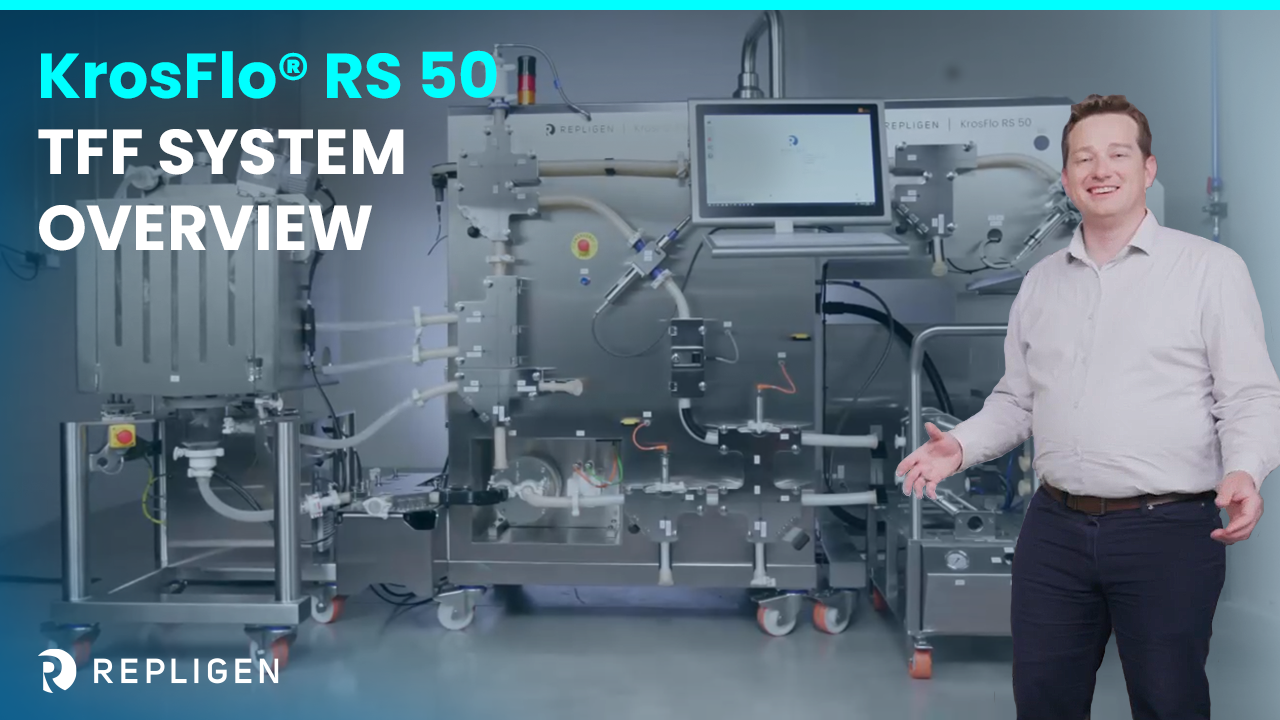

KrosFlo RS 50 TFF System Overview

In this video, Lucas Smith gives us a closer look at the innovative KrosFlo® RS 50 TFF System by Repligen. Discover unique features such as intelligent mixing and end-to-end automation. This single-use TFF system supports 1” line size tubing and membrane areas ranging between 5 and 20m2.

Scale up Streamlined

Designed as a single standardized platform and not as standalone systems, KrosFlo® RS share the same industrial grade components and automation capabilities across the entire system series. With the same software, hardware, controls and cGMP compliance built into every system, challenges in scale-up are significantly reduced, allowing you to confidently maintain your process as you scale.

|

|

|

|

|

|

|---|---|---|---|---|---|

| System |

RS 10 |

RS 20 |

RS 30 |

RS 40 | RS 50 |

| Tubing Diameter | 1/8" | 1/4" | 1/2" | 3/4" | 1" |

| Flatsheet | 0.01 - 0.1 m2 | 0.1 - 0.5 m2 | 1 - 5 m2 | 1 - 10 m2 | 5 - 20 m2 |

| Hollow Fiber | 0.02 - 0.6 m2 | 0.05 - 1.0 m2 | 0.05 - 5 m2 | - | 4 - 34 m2 |

| Recirculation Pump (Diaphragm) |

0.5 LPM | 3.4 LPM | 20 LPM | 41 LPM | 83 LPM |

| Centrifugal | 1.15 LPM | - | - | - | - |

| Peristaltic | 0.34 LPM | - | - | - | - |

Upgrade to RPM™ for Real-time Concentration Control

Integrated with the CTech™ FlowVPX® in-line spectrophotometer, unlock advanced analytical capabilities based on real-time concentration data. Reduce variability, offline sampling and dilution steps.

- Greater control and reproducibility

- Increase efficiency and yields with reduced cycling

- Reduce risk with real-time concentration data

Explore the System Components

KrosFlo® RS single-use Tangential Flow Filtration (TFF) systems incorporate the most advanced engineering principles alongside unique hardware to achieve unprecedented automation, hold-up volume and process control.

Click on the tabs to explore features of the different KrosFlo RS Systems.

KrosFlo® RS 10 TFF System

Click on the links to explore different features.

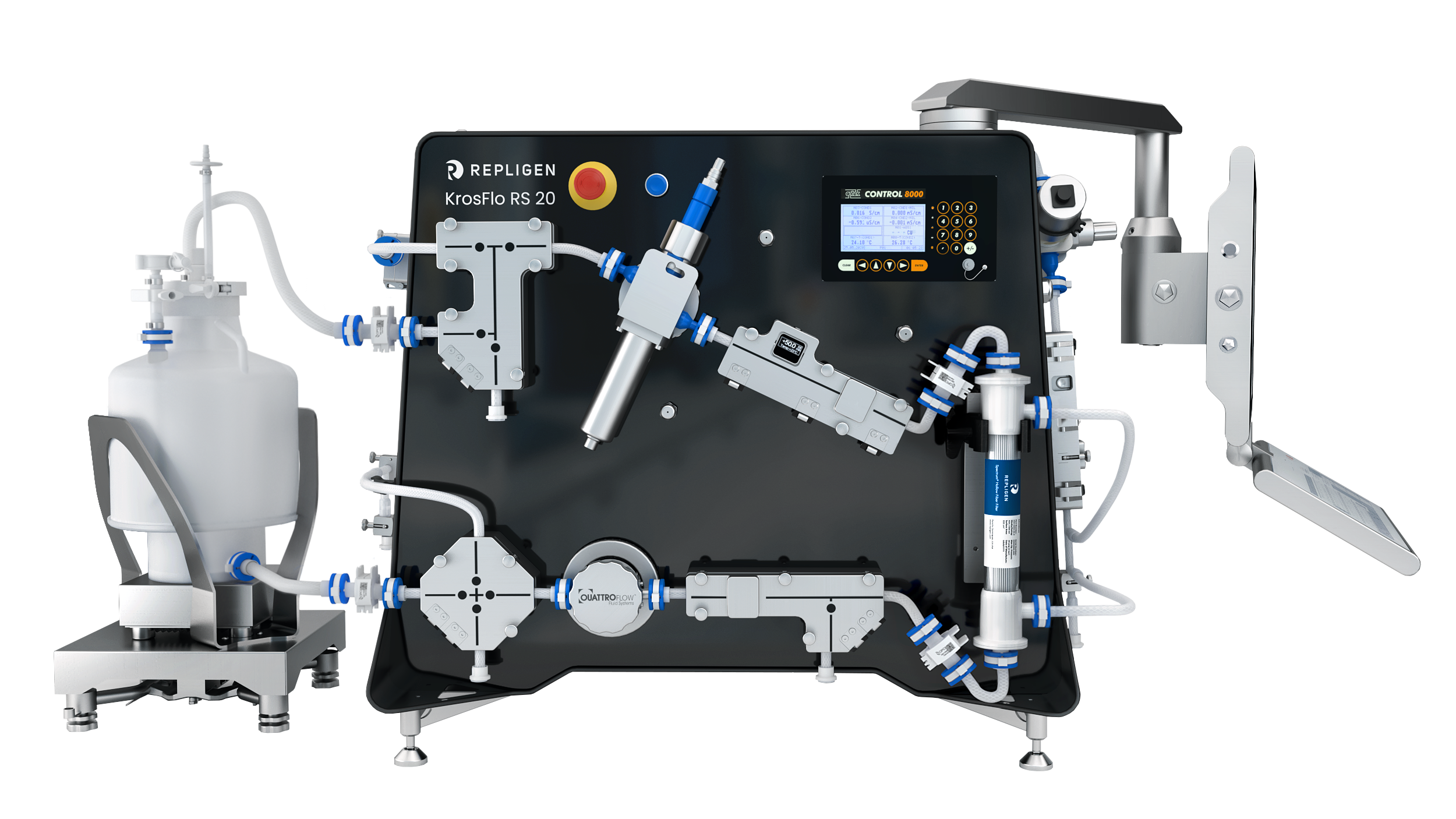

KrosFlo® RS 20 TFF System

Click on the links to explore different features.

KrosFlo® RS 30 TFF System

Click on the links to explore different features.

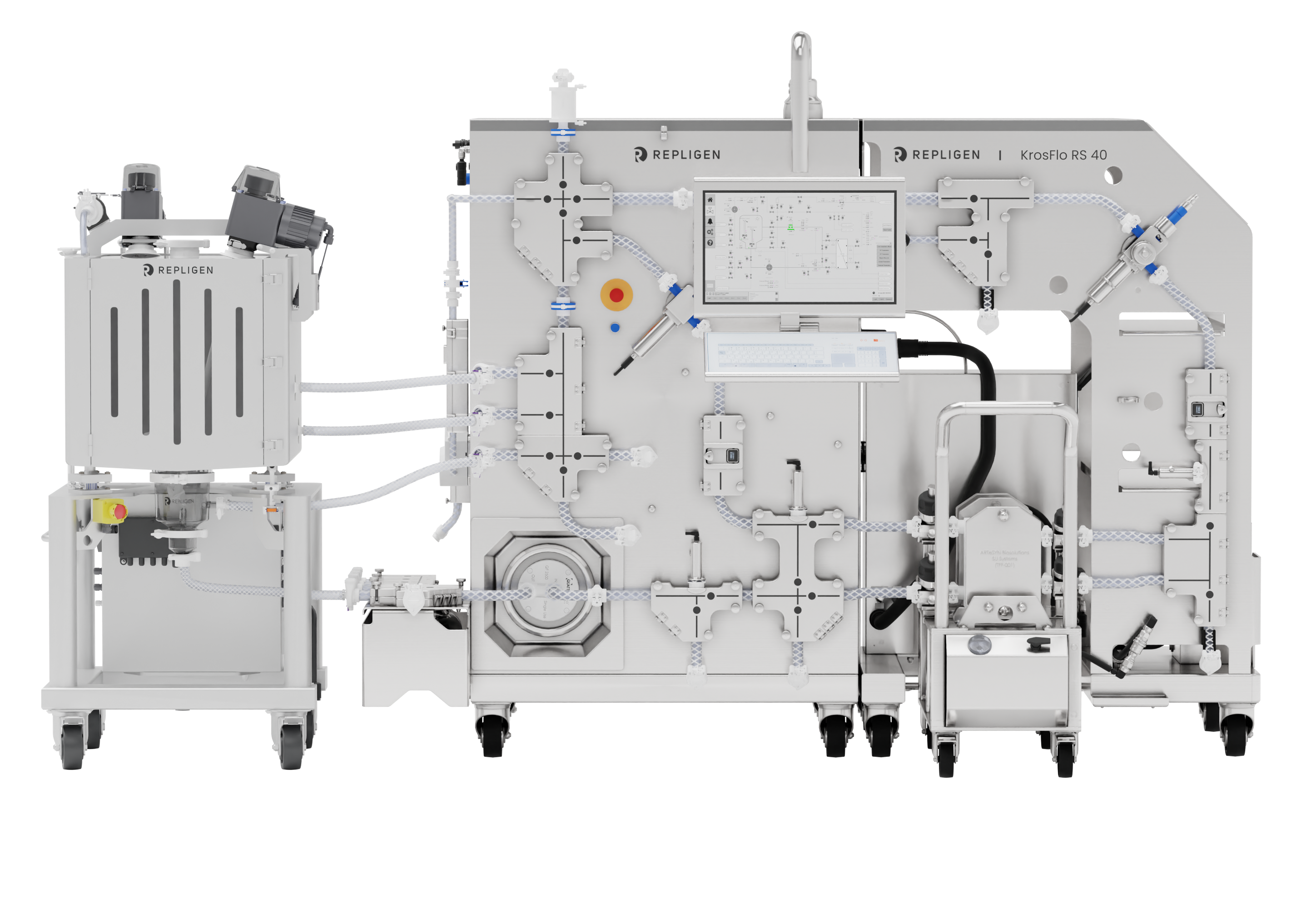

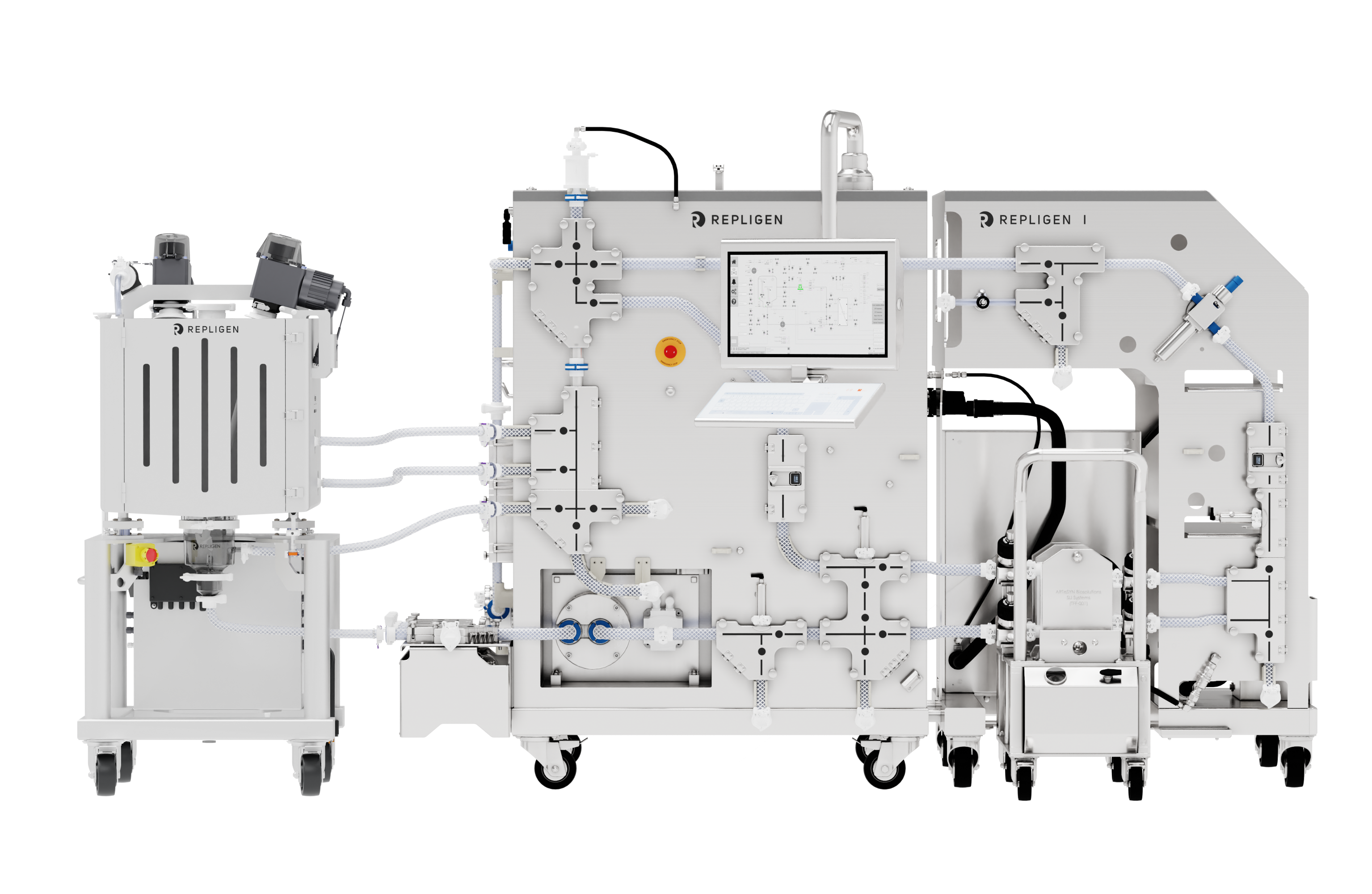

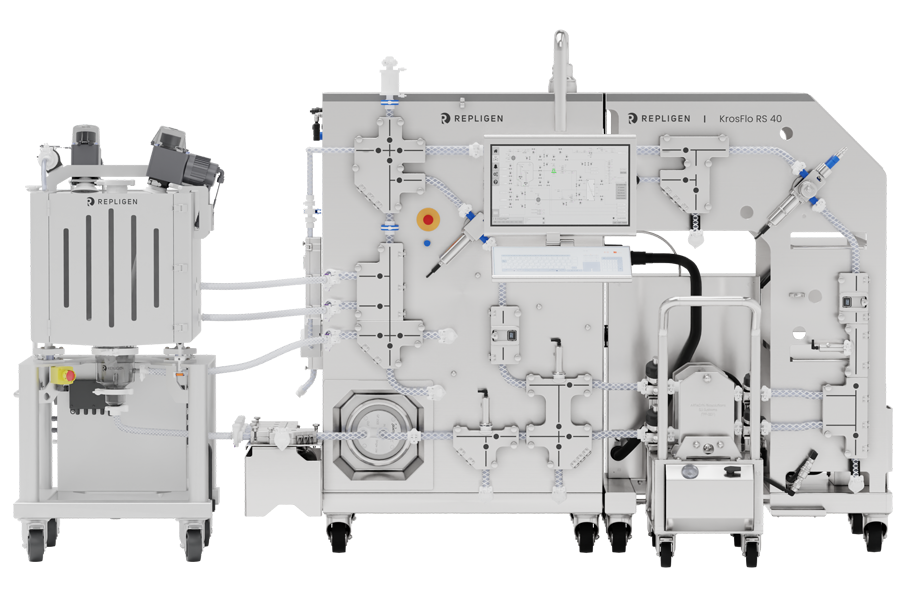

KrosFlo® RS 40 TFF System

Click on the links to explore different features.

KrosFlo® RS 50 TFF System

Click on the links to explore different features.

Error-free installation in minutes with pre-assembled flow paths

ProConnex Flow Paths, pre-assembled and specific to the KrosFlo® RS TFF System, are intuitively designed for simple, mistake-free installation. All system sensors are pre-calibrated and assembly is done in minutes with no confusing instructions.

Click on the left/right arrows or swipe to see flow path assembly steps for the different KrosFlo® RS TFF Systems.