ProConnex® MixOne CB-X

A cutting-edge single-use mixing system for bioprocess products that boasts exceptional performance for shear-sensitive substances.

Efficient, gentle and robust

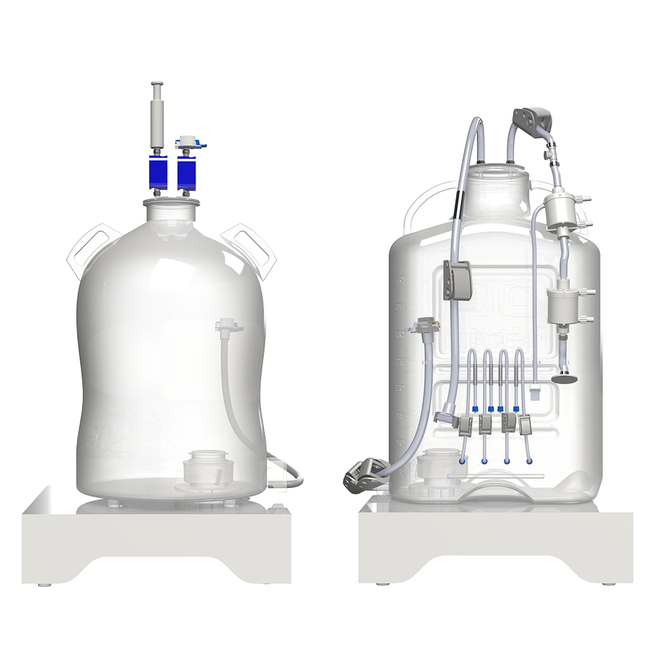

The ProConnex® MixOne Carboy system provides safe and easy handling of valuable products, equipped with state-of-the-art Truelev Mixing Technology in both square and round rigid carboy containers. Optimized for mixing, these containers offer reliable low shear mixing and efficient resuspension capabilities, making this an ideal solution across the bioprocessing workflow. Whether you need precision mixing for upstream or downstream processes, the ProConnex® MixOne Carboy system ensures consistent and effective results.

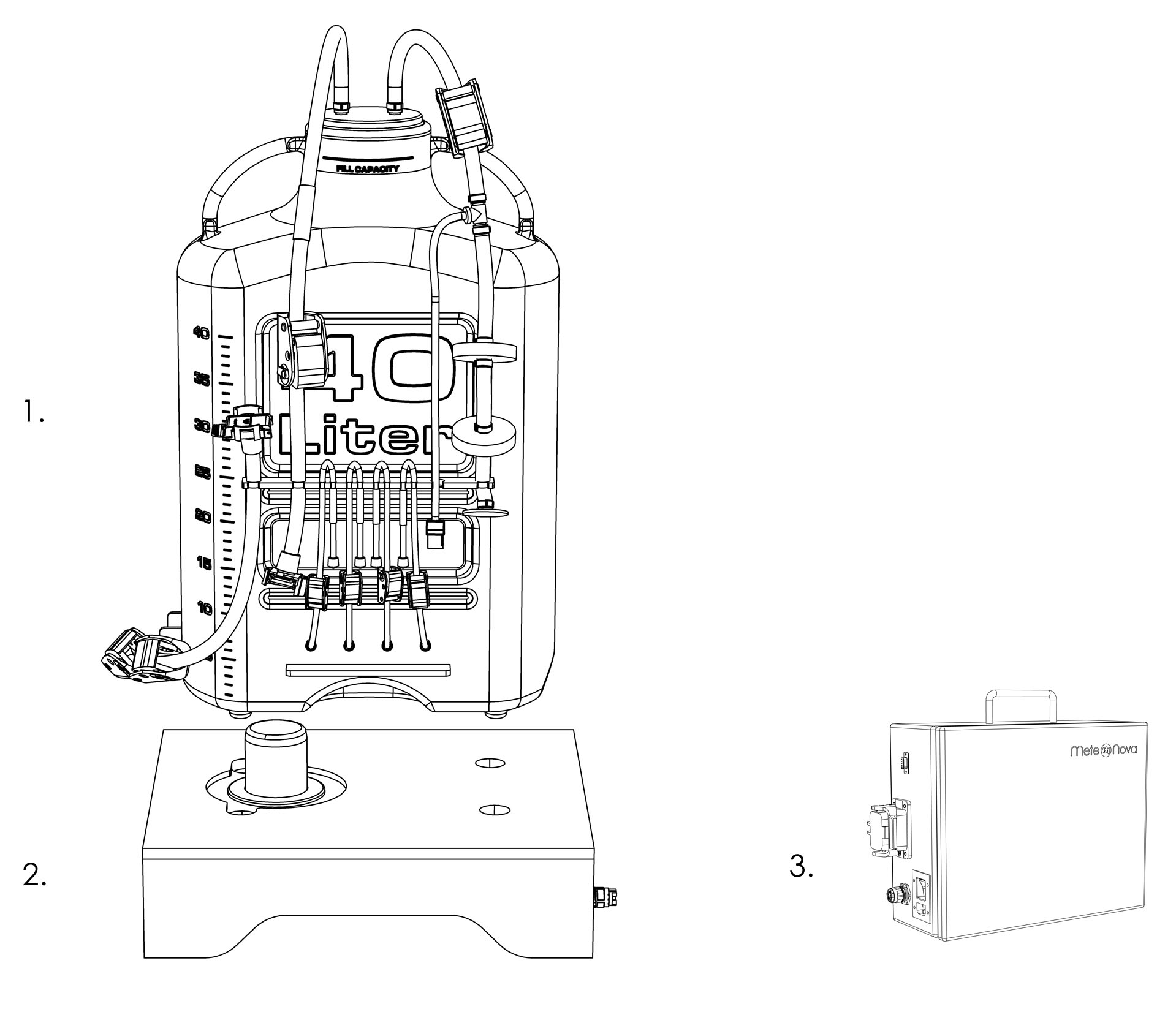

For those high-value bioprocess drug products where superior mixing, secure storage, or safe transportation of pharmaceutical products is critical, the ProConnex® MixOne Carboy system offers industry leading mixing technology, Truelev, integrated into a secure single-use rigid carboy which can be easily and safely transported in the ProConnex® MixOne Secure Carrier. The ProConnex MixOne Carboy system has three key components:

- The sterile single-use rigid carboy assembly ensures the safety of its contents versus traditional bag technology. And the TrueLev bearing-less fully levitating mix head makes it ideal for low volume shear sensitive products providing a reliable, repeatable mixing result every time.

- A reusable drive unit platform where the carboy container docks for mixing can be operated through your existing external control system or through a hand-held control panel.

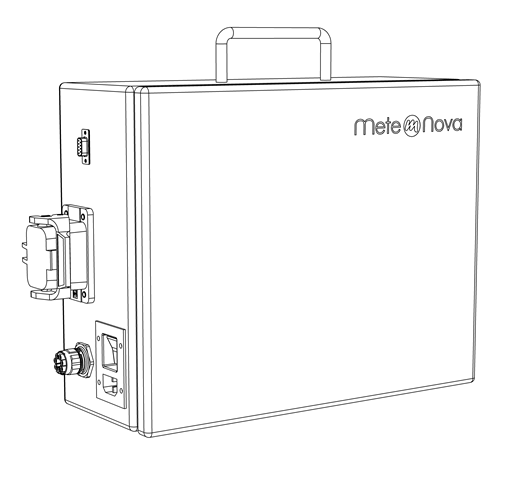

- A ProConnex® MixOne Secure Carrier designed for the safe transport of ProConnex MixOne square carboy containers. This solution provides a reusable, robust shipping platform enabling secure transport of ProConnex MixOne carboys.

In mixing, shape is everything

Achieve optimal mixing across the entire process map with a configurable mixing platform and two carboy geometries to support a variety of applications.

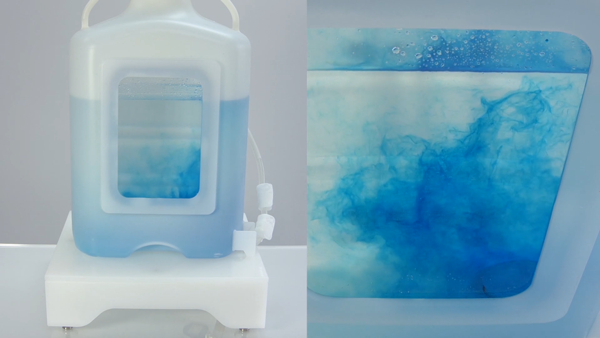

- Round shaped carboy helps promote vortex formations in the liquid, keeping the surface turbulent while generating a spinning vortex which extends from the surface to the mix head. Ideally suited for pulling floating powders and salts into solution.

- Square shaped carboy helps eliminate vortex formations in the liquid, keeping liquid surface flat while generating convection flow in a bottom to top motion. Ideally suited for shear sensitive solutions and suspensions that benefit from a gentle mix.

Why ProConnex® MixOne Carboy System?

Superior mixing

Superior mixing performance at low shear, utilizing the Truelev Technology combined with optimized hard container design.

TRUE PROTECTION BY DESIGN

The robust design makes the container easy and safe to transport.

MODULAR PRODUCT OFFER

The ProConnex® MixOne Carboy System is made to be adaptable to your specific needs of how to connect to the system - meaning the platform allows for many different options of connectors, tubing, and filters, etc.

IDEAL FOR SMALLER VOLUMES

Smaller volumes are often associated with plastic bags. The ProConnex® MixOne Carboy System offers an option to those applications and enables an environment similar to the stainless steel vessel.

NO FUSS ASSEMBLY

The easy installation eliminates any potential operator errors, ensuring a perfect mixing process.

SAFE CARBOY TRANSPORT

ProConnex® MixOne Secure Carrier is a safe and robust transportation unit to keep your filled ProConnex® MixOne carboys safe during transport, ensuring no damage to your valuable end product.

Resources

Mix up to 350 RPM in just a heartbeat.

Bearing less design that does not need liquid to lubricate a bearing.

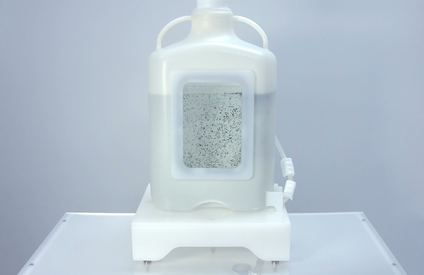

The off bottom lift promotes a quick and efficient resuspension of settled solids.

Even at very low speed. This video shows 2% of max power.

The ProConnex® MixOne Carboy System is modular with an extensive component library of different sizes, tubes, fittings, etc. The one showed in the video is 40L. Please consult your sales rep for your particular needs.

Stirbars are typical lab mixers that have limited capacity and performance when it comes to mixing at production scale. The ProConnex® MixOne Carboy System mixer platform is designed to meet and exceed the pharma needs at a production scale, with unparalleled mixing performance in combination with the TrueLev bearingless technology that eliminates any particulate shedding that is related to stir bars.

The container with a window is perfect for visual evaluation of your mixing performance. It is not a standard product, but it is available upon request. A typical application would be in your R&D evaluation step as a bridge before moving to product models without window. The window model does not come as irradiation compatible and because of that in most cases not suitable for production.

The ProConnex® MixOne Carboy System is easily operated by docking the container to the drive unit platform. The mixing system can be controlled in two ways:

Digital through either a handheld control panel or through your existing external control system

Through PLC

The ProConnex® MixOne Carboy System container in the video is made for low shear mixing of media that requires a sterile and aseptic environment. After filling through the filling line it can remain in its closed system for storage. When the product is to be used, the ProConnex® MixOne Carboy System container is simply reinstalled on the platform and the mixer turned on to resuspend the product. To check the quality of the product and the mixture the system is equipped with four aseptic samples lines made of C-flex tubing that can be welded on a sampling container. To facilitate ease of use during operation and installation, it is equipped with tube holders locating, protecting, and preventing tangling of the tubes during handling. The vent line has a pressure sensor to leak test the unit before use. The container has a low point drain line for easy emptying with an aseptic quick connect at the end of the line.

- Carboy single-use assembly

- Platform

- Control cabinet

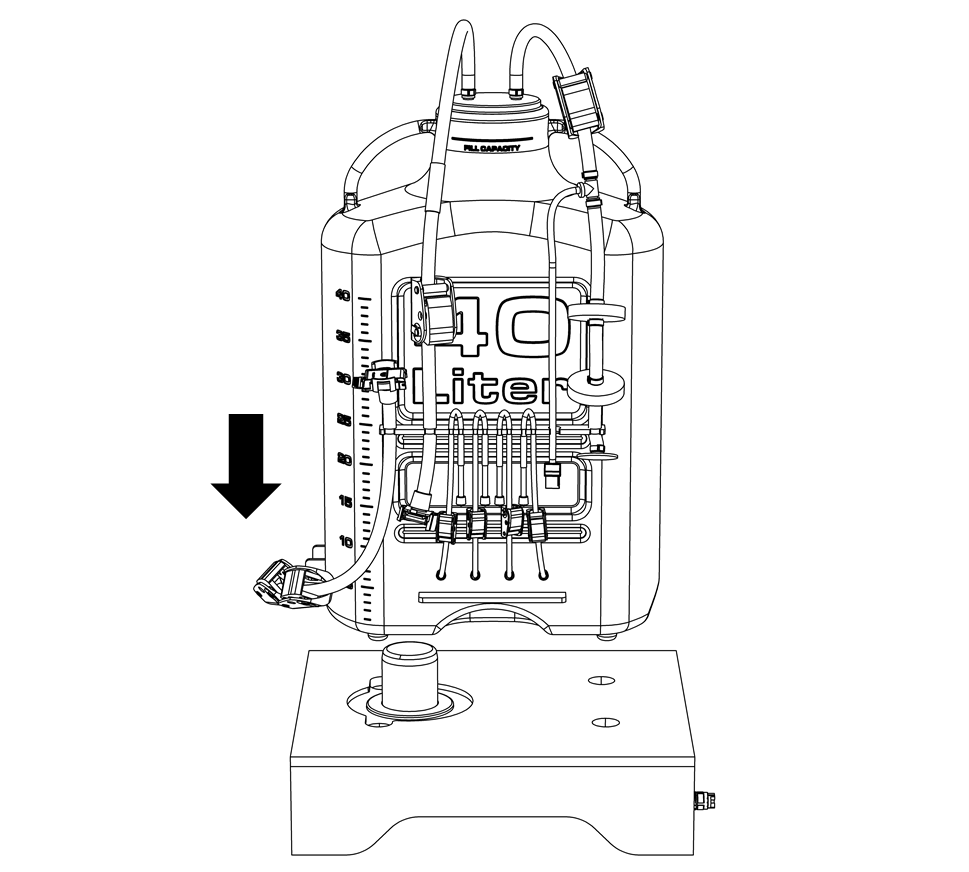

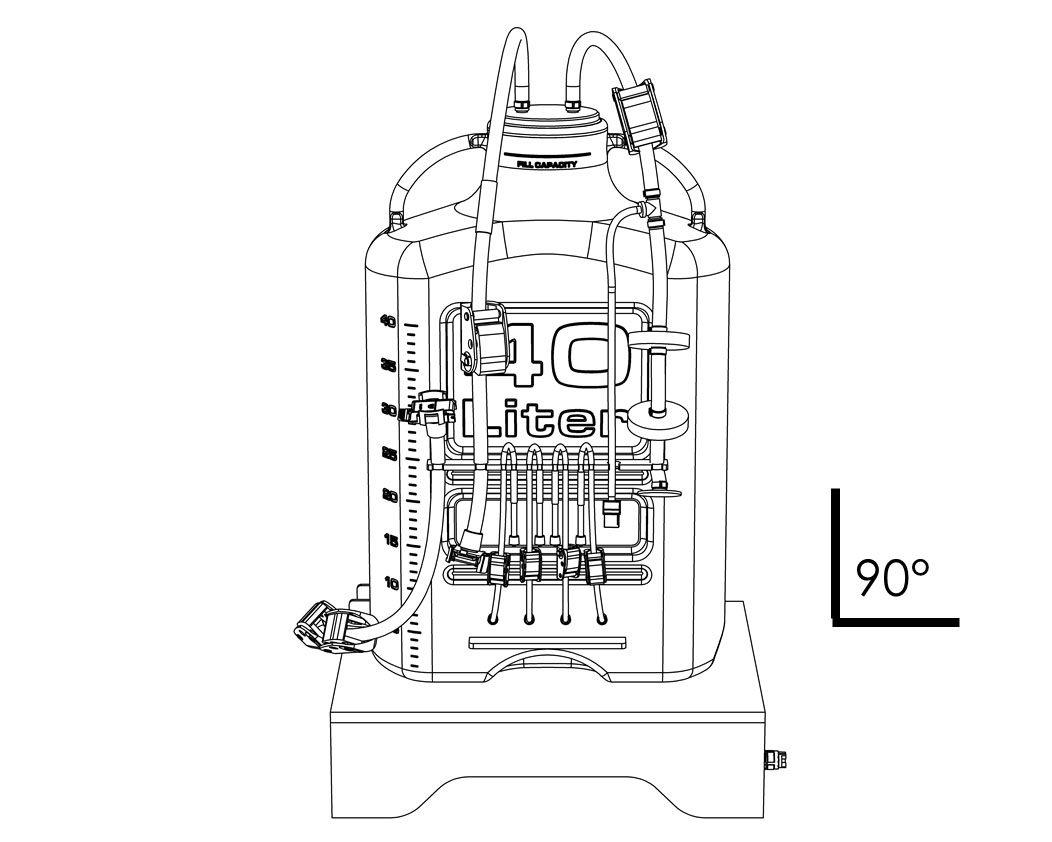

Carefully place the Single-Use Assembly on the Drive Unit Platform so that the Tank Plate is positioned on top of the Drive Unit and the feet of the Single-Use Assembly are placed in the corresponding holes on the Top Plate of the Drive Unit Platform.

Make sure that Single-Use Assembly is resting on the bottom of the carboy while positioned on the Drive Unit Platform and feet are in the four locating holes. It should not be resting on its feet or the tank plate. The Single-Use Assembly should be perpendicular to the platform, otherwise, the mixing properties may be reduced.

Speed range: 0-350 rpm.

Material and chemical compatibility: The platform is made from polypropylene and can be cleaned with alcohol.

Temperature range: The designed operating temperature span is between +2C and +40C / 36F and 104F.

Tube/port setup: The system can be provided with many different filters, tubings, connectors and most other types of components on the market to meet your needs.

Safety features:

The ProConnex® MixOne Carboy System is a robust closed system that effectively prevents any accidental product leakage and potentially harmful exposure. The robust design also allows for ergonomic handling, either by hand or with lifting aids, thanks to the integrated handles on top.

The ProConnex® MixOne Carboy System is equipped with a tube handling system that prevents the tangling of tubes.