KrosFlo® TFDF® Systems

Game-changing TFDF® (Tangential Flow Depth Filtration) technology that simplify and intensify upstream viral vector bioprocessing, ideal for AAV, lentivirus, oncolytic, retrovirus, adenovirus, exosomes, and cells on microcarriers.

INNOVATION BREAKTHROUGH

Unlocking High-Yield Virus Production in AAV and Lentivirus

Intensification Starts Here!

Discover how KrosFlo® TFDF® based process intensification delivers breakthrough in high virus production for transient and stable producer cell lines combined with simplified clarification compared to batch cell culture.

- Implement TFDF to mitigate cell density effect

- Boost virus production >10X and reduce production scale ~20x compared to a 200L batch process

- Simplify clarification techniques to streamline your production process

INNOVATION BREAKTHROUGH

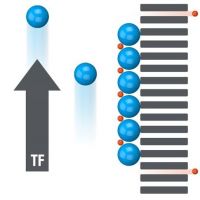

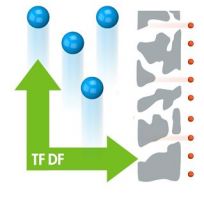

TF + DF = TFDF® Combined Benefits

Tangential Flow

High cell density

Poor product passage

Depth Filtration

Low cell density

Excellent product passage

Tangential Flow Depth Filtration

High cell density

Excellent product passage

INNOVATION BREAKTHROUGH

INNOVATION BREAKTHROUGH

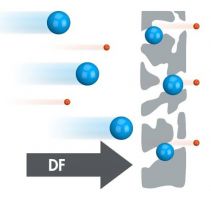

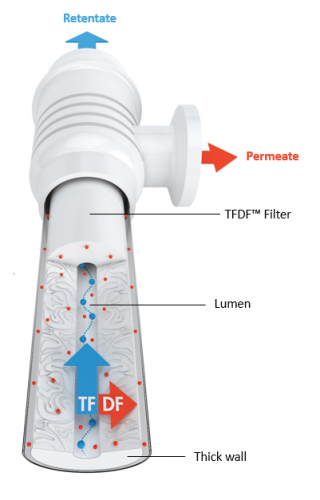

Novel TFDF® Filter

The thick-walled 2 - 5 µM tubular filter captures cells and cell debris with reduced fouling and negligible product retention. The feed stream enters the bottom port. The retentate travels through the lumen and exits at the top of the tube. The permeate exits the enclosure through the lower permeate port.solution. The combination of tangential flow and depth filtration in one filter produces a high-flux, high-capacity solution. h

INNOVATION BREAKTHROUGH

Synergistic Benefits

- Low concentration polarization minimizes fouling

- Short, highly inter-connected paths do not retain product

- Small footprint

- 2-5 micron pore size for large biomolecules

INTEGRATED

Filter, Flow Path and System as One Solution

KrosFlo® TFDF® Filter

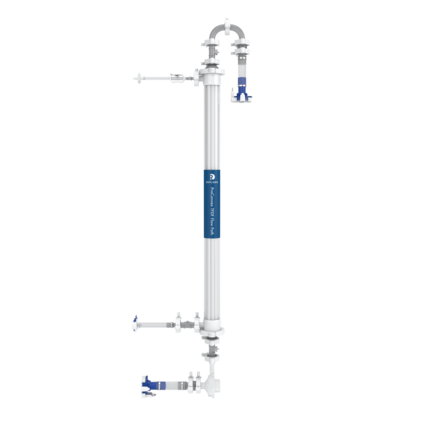

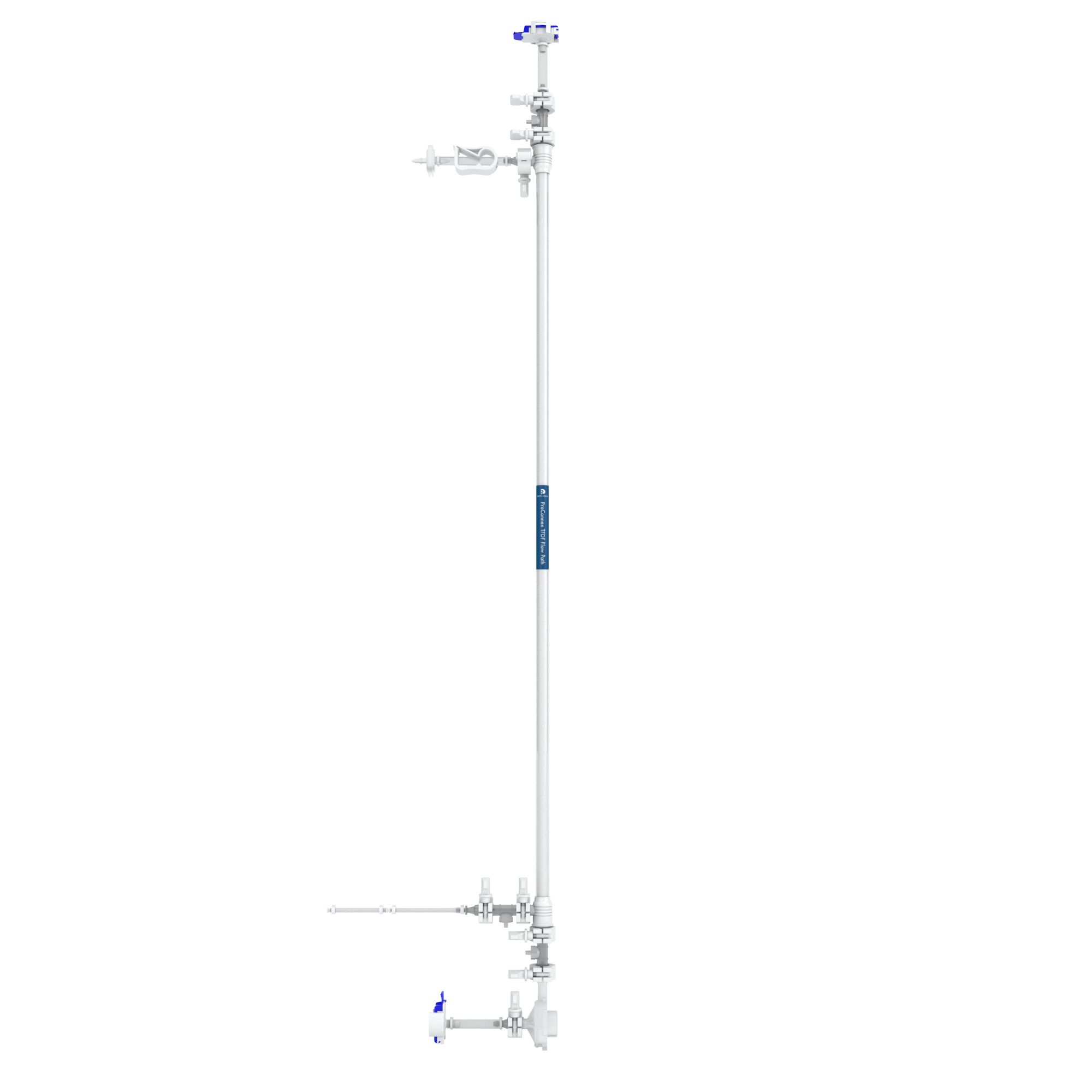

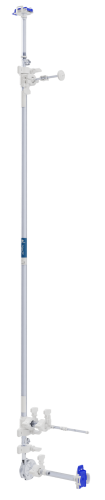

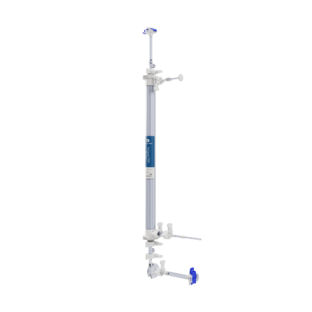

ProConnex® TFDF® Filter Assembly

KrosFlo® TFDF® Systems

INTEGRATED

INTEGRATED

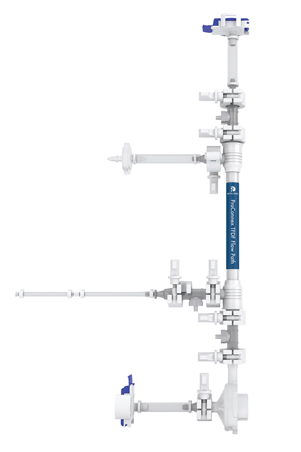

Complete, Ready-to-use TFDF® Filter Assemblies

Single-use, Gamma-irradiated and closed ProConnex® TFDF® Flow Paths arrive dry, free of sodium hydroxide, glycerin, preservative and ethanol, for a zero flush start state. ProConnex® TFDF® Flow Paths are complete assemblies that include the TFDF® Filter, a disposable pump head, integrated sensors, tubing and aseptic connectors.

TFDF® Filter

Surface Area: 3 cm2

Surface Area: 30 cm2

ProConnex® TFDF®

Flow Path

Surface Area: 3 cm2

Surface Area: 30 cm2

Surface Area: 50 cm2

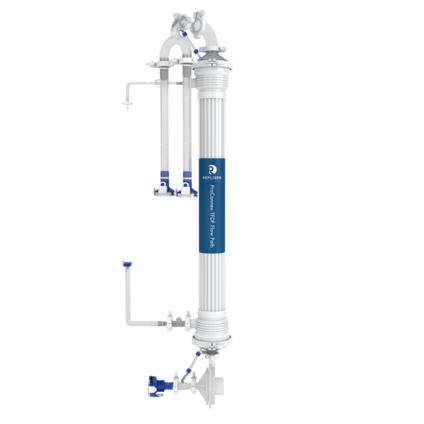

ProConnex® TFDF®

Flow Path

Surface Area: 150 cm2

ProConnex® TFDF®

Flow Path

Surface Area: 450 cm2

Surface Area: 750 cm2

Surface Area: 1500 cm2

Surface Area: 2100 cm2

ProConnex® TFDF®

Flow Path

Surface Area: 6000 cm2

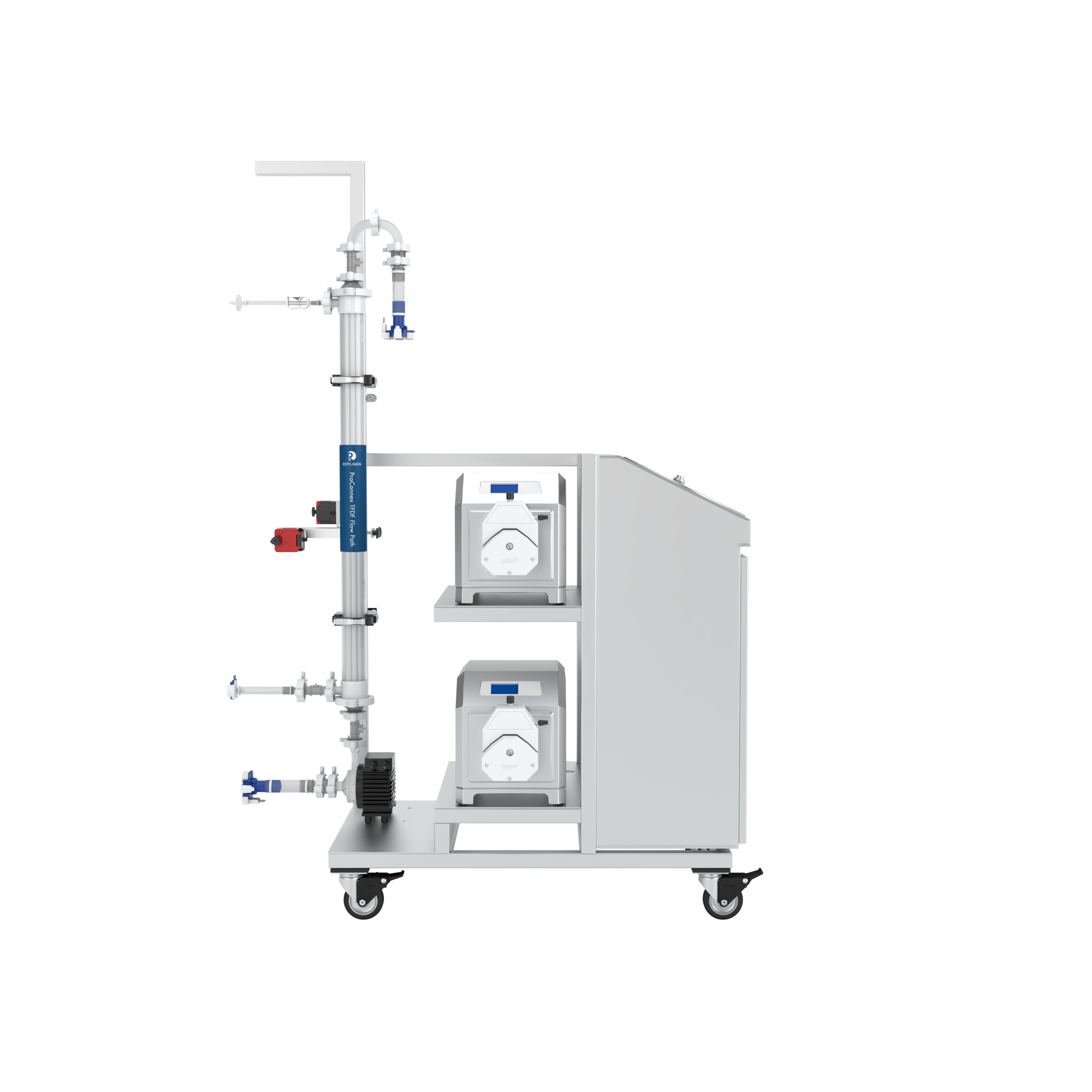

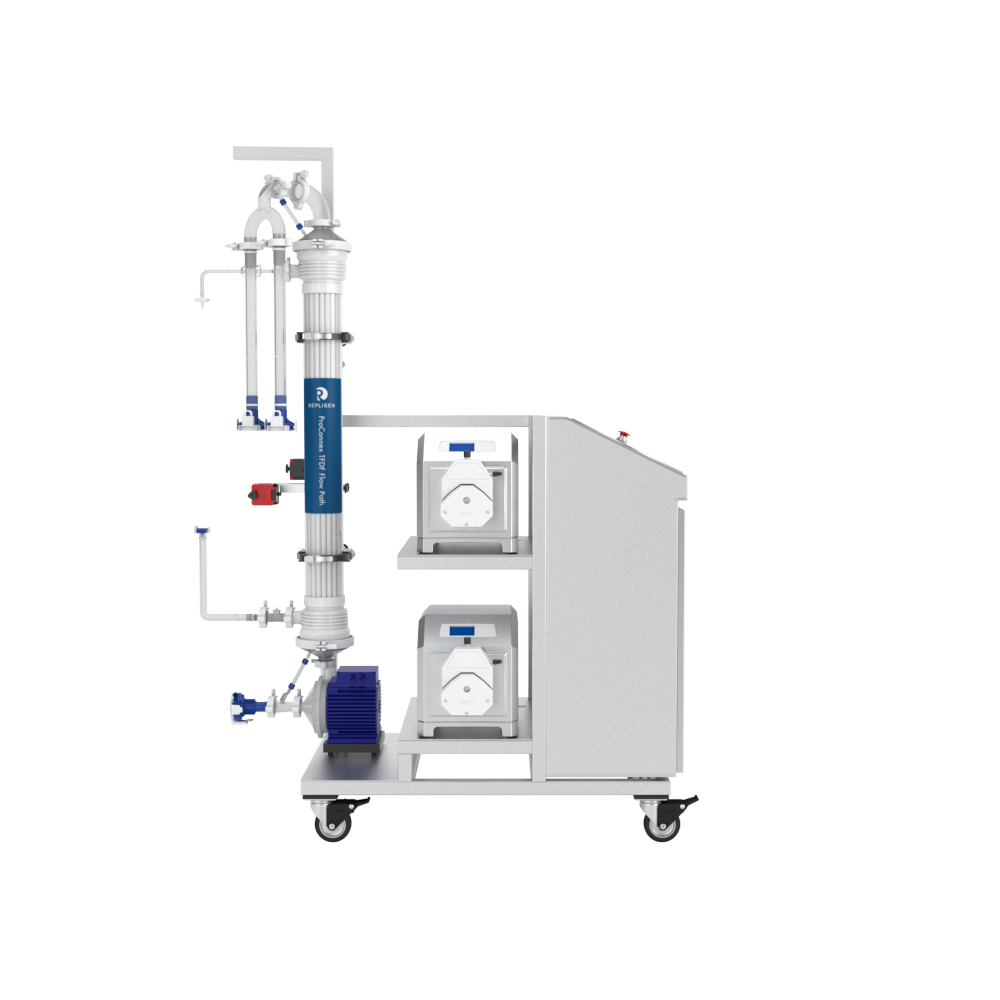

Industrial grade components and extended automation allow for confident process scaling. With the same software, hardware, controls and cGMP compliance built into every system, process change challenges in scale-up are removed.

READY TO SCALE FAST

READY TO SCALE FAST

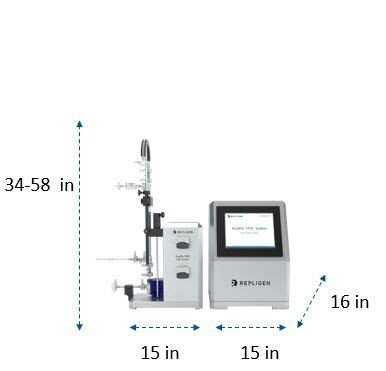

Maintain processes while scaling to production

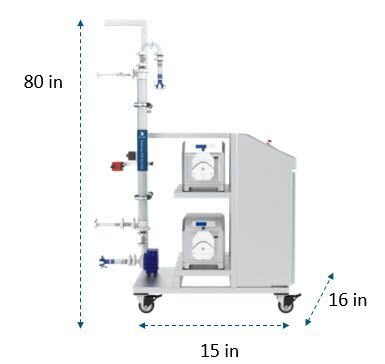

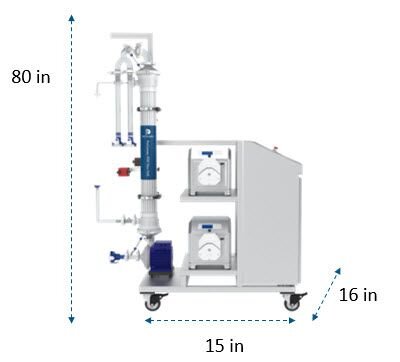

The KrosFlo® TFDF® System delivers application-specific process control logic for optimal TFDF process performance. Systems scale from 1 L to 2000 L in a small footprint of 1 m2 for both pilot (31 inch x 42 inch) and process (37 inch x 42 inch) systems.

KrosFlo® TFDF Lab System

1 - 50 L volume

3 - 160 cm2 surface area

KrosFlo® TFDF® Pilot System

1 - 500 L volume

500 - 1600 cm2 surface area

KrosFlo® TFDF® Process System

50 - 2000L volume

3000 - 6000 cm2 surface area

READY TO SCALE FAST

Capacity increases with tube number and length

To ensure linear scalability from 1 to 2000 L, the tube length and the number of tubes per enclosure increases. Tube length increases from 20 cm to 108 cm. The effective length of the filter may be less than the physical length of the filter. The number of tubes increases from 1 - 40 per enclosure.

Number of tubes

1 tube

Surface area: 3 cm2

Recommended Volume: <1 L

1 tube

Surface area: 150 cm2

Recommended Volume: <50 L

10 tubes

Surface area: 1500 cm2

Recommended Volume: <500 L

40 tubes

Surface area: 6000 cm2

Recommended Volume: <2000 L

* additional sizes available

Length of tubes

Physical length: 20 cm

Effective length: 2 cm

Surface area: 3 cm2

Physical length: 108 cm

Effective length: 108 cm

Surface area: 150 cm2

KrosFlo® TFDF® Systems

The KrosFlo® TFDF® System delivers a complete solution for optimized tangential flow depth filtration, with integrated process control logic and a single-use, Gamma-irradiated ProConnex® TFDF® Flow Path with integrated sensors.

Click on the tabs to explore features of the different KrosFlo® TFDF® Systems and Flow Paths.

KrosFlo® TFDF® Lab System

1 - 50L volume

3 - 160 cm2 surface area

Click on the links to explore different features.

KrosFlo® TFDF® Pilot System

1 - 500L volume

500 - 1600 cm2 surface area

Click on the links to explore different features.

KrosFlo® TFDF® Process System

50 - 2000L volume

3000 - 6000 cm2 surface area

Click on the links to explore different features.

ProConnex® TFDF® Flow Path

Click on the links to explore different features.

KrosFlo TFDF Lab Flow Paths

Off-the shelf, single-use, gamma-irradiated and closed TFDF Lab Flow Paths arrive dry, free of sodium hydroxide, glycerin, preservative and ethanol, for a zero flush start state.

Custom KrosFlo TFDF Pilot and Process Flow Paths

When scaling up, configure a flow path to meet your process requirements for your pilot and process KrosFlo TFDF Systems. All KrosFlo TFDF flow paths are single-use, gamma-irradiated and arrive dry, free of sodium hydroxide, glycerin, preservative and ethanol, for a zero flush start state.

Replace sluggish messy depth filtration with combined tangential flow and depth filtration. No need to load multiple filters or hunt for parts. At 1L through 2000L, connect one fully integrated filter module and go -- at flux speeds up to 1950 LMH.

If you have three minutes, then you have enough time to install a TFDF® flow path. Mount the device, make a few connections and you’re done - without ever breaking a sweat.

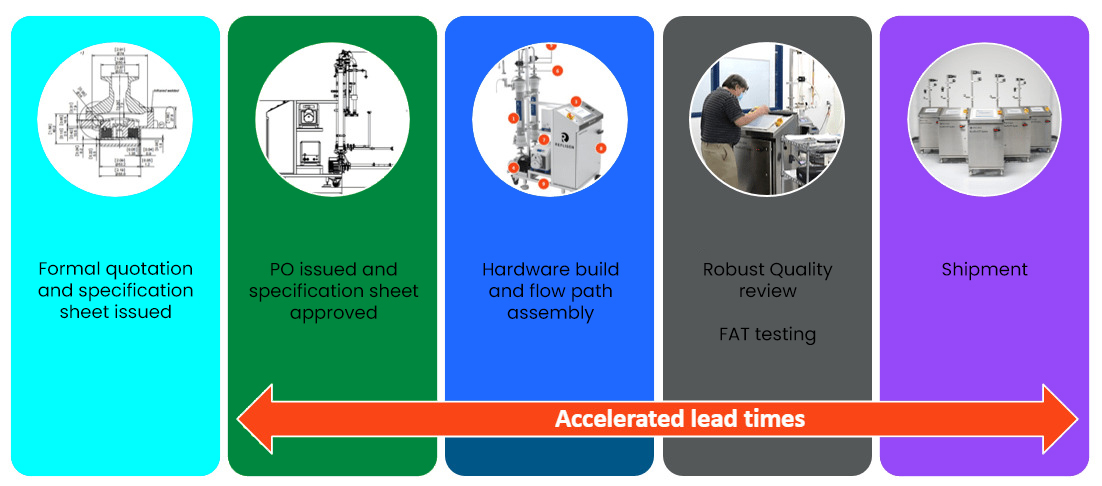

Manufacturing Centers of Excellence

Repligen develops and manufactures products for the biopharmaceutical industry under an ISO 9001 quality management system. We focus on the timely delivery of high quality, consistent and robust products, to ensure business continuity for our customers.

Repligen manufacturing sites are located in Massachusetts, California, and New Jersey in the United States and in Sweden, France, The Netherlands, Germany and Estonia.

Expert Project Management

Customer First.

Support is part of the Repligen DNA. Our goal is to provide exceptional customer experience, and to support the efficient and successful adoption and implementation of all Repligen products and services.

- Field Application Support

- Customer Service

- Field Service Engineers

Resources

Process intensification for lentiviral vector manufacturing using tangential flow depth filtration

by Robert M. Tona, Reeti Shah, Kimberly Middaugh, Justin Steve, João Marques, Blair R. Roszell, Cindy Jung

Cell Press, March 2, 2023

Production of Lentiviral Vectors Using a HEK-293 Producer Cell Line and Advanced Perfusion Processing

by Michelle Yen Tran and Amine A. Kamen

Frontiers, June 14, 2022

Lentiviral vector manufacturing process enchancement utilizing TFDF® technology

by Thomas Williams, Oliver Goodyear, Lee Davies, Carol Knevelman, Michael Bransby, Kyriacos Mitrophanous and James Miskin

Cell and Gene Therapy Insights, April 2020