XCell™ Lab System

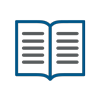

NEW | Designed and engineered as a complete solution, the XCell™ Lab System integrates devices, controller and software, enabling low volume process intensification ready for scale-up.

SIMPLIFY AND INTENSIFY

Configurable set-up delivers high throughput

Permeate pressure data for improved characterization

Integrated pressure sensors

INTEGRATED SYSTEM

All components validated as a complete system

Easy connectivity to any bioreactor

2X Device capacity

POWERFUL INTERFACE

Software designed for technical control and easy navigation

User-definable HMI customizations

INTEGRATED SYSTEM

INTEGRATED SYSTEM

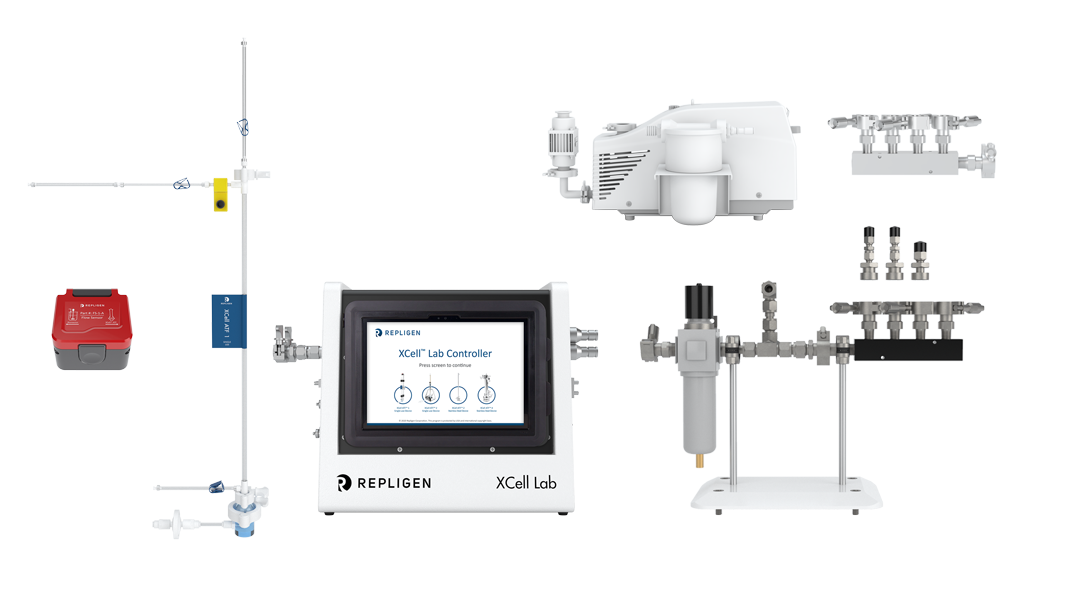

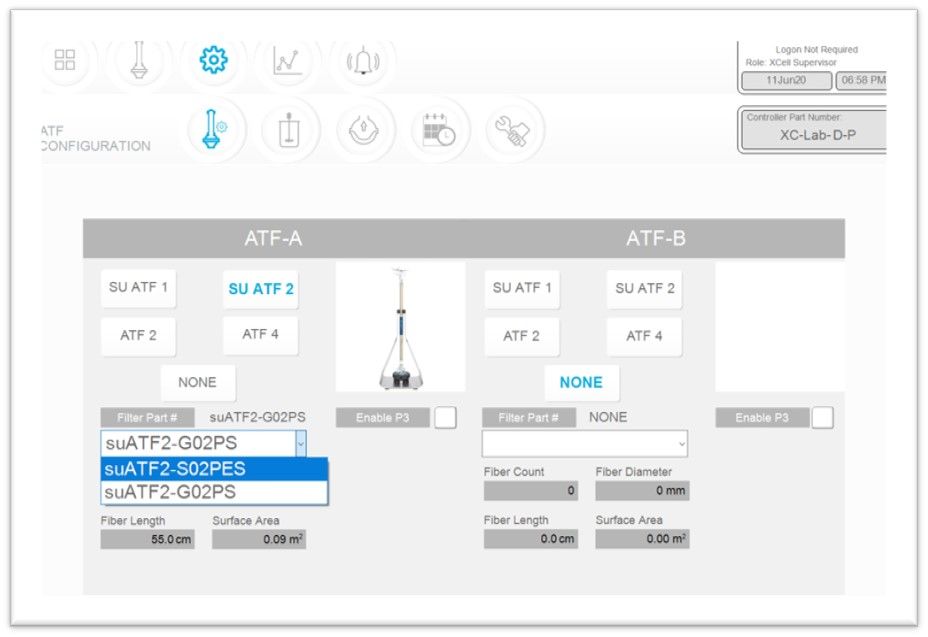

Configurable set-up delivers high throughput

One XCell™ Lab Controller can support up to two XCell ATF® Devices that can be configured on either one or two bioreactors.

A single manifold can support up to 8 XCell ATF® Devices

SAPA + Vacuum Manifold Set-up

-

Adapters provided to fit all connections

-

Pressure regulation and relief

-

Air supply filtration

-

Supports up to 4 controllers

Up to 4 XCell™ Lab Controllers

-

1 tablet per controller

-

Supports up to 2 devices

Up to 2 XCell ATF® Devices per Controller

-

Flexible bioreactor configuration

-

Supports ATF 1,2,4

POWERFUL INTERFACE

POWERFUL INTERFACE

5th generation controller with precision engineering

The XCell™ Lab controller is engineered for robust intensification and user-friendly experience.

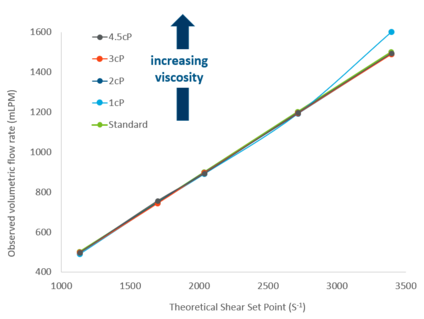

- Maintain precise flow rates even at high viscosities during the late stages of intensification development using a control logic loop with re-engineered hardware.

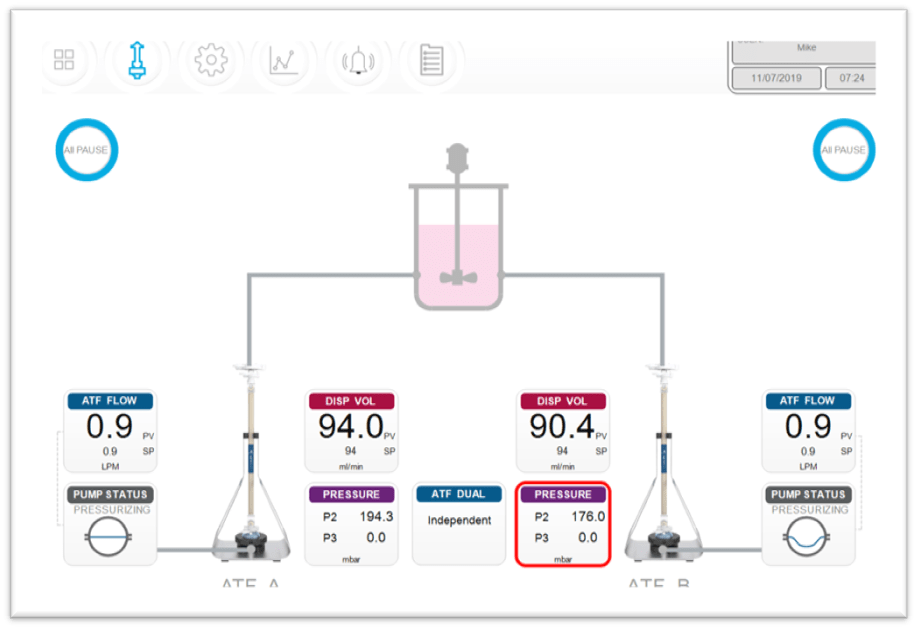

- Monitor real-time filter status using a recording of permeate pressure data.

- Configure alarms for key process events at just the right moment, reducing errors and maximizing efficiency.

- Visualize key trending data on a tablet-based graphical interface designed for clarity makes the system enjoyable to use.

- Increase productivity by deploying up to two filtration devices that can be configured on either one bioreactor or two.

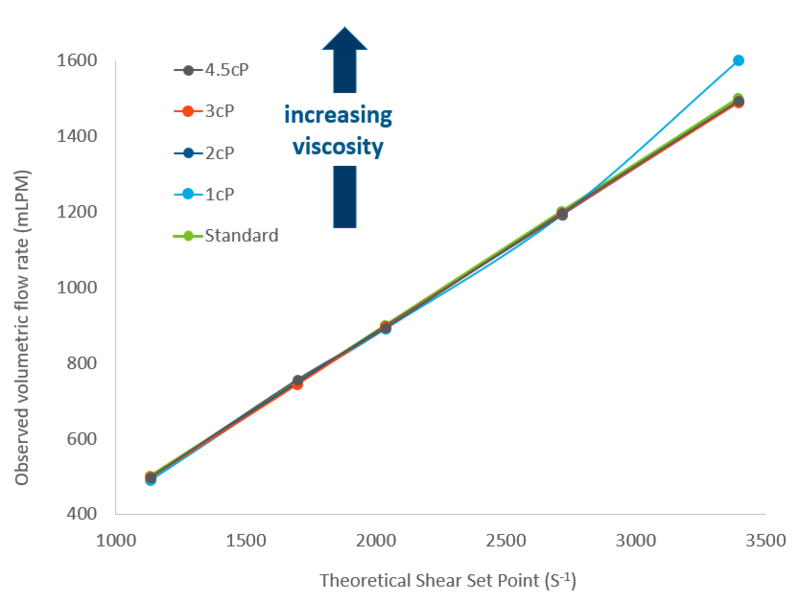

Consistent flow rates with increasing viscosity help ensure robust development and manufacturing scale-up.

- Overlapping lines demonstrate that the correlation between volumetric flow rate and shear set point remains consistent with increasing viscosity.

- The consistent flow rate is maintained using a new valve and control logic loop that enables precision pumping.

POWERFUL INTERFACE

POWERFUL INTERFACE

Software designed for technical control

Modern minimalist layout

- Image adapts to actual equipment in use

- Fast familiarization through colors and format

- Alarms graphically associated with specific component

Graphics confirm text input

- Single button selection (iPhone-like)

- Integrated device pictures and part numbers

- Automatic shear calculations

POWERFUL INTERFACE

POWERFUL INTERFACE

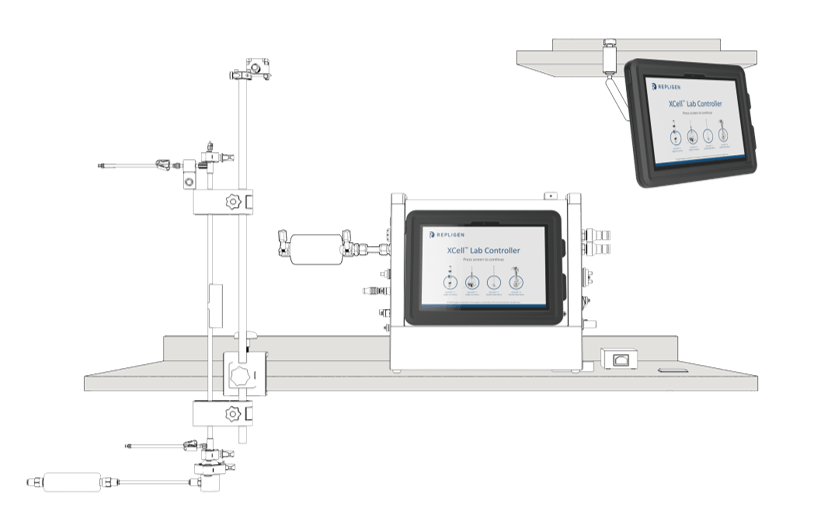

An interface ready for your lab environment

-

Splash-proof case protects against lab hazards and accidents

-

Mountable arm adjusts position to your environment

-

So simple, no keyboard required

The XCell™ Lab Controller solves your productivity puzzle with new engineering, increased throughput and more process data. Turn the frustration of endless permutations into a simple solution that generates more cells, and more product…faster.

Intensification is worth it. Build an intensified upstream suite brick by brick with XCell ATF® systems. Make twice as much product in half the time as you watch VCD grow and shrink bioreactor sizes within the same facility footprint.

OMG life gets busy. Set-up industry-best cell culture intensification in less than 30 minutes with the design simplicity of XCell ATF® devices. Celebrate more product at work…and still have time for the special moments at home. YGTI.

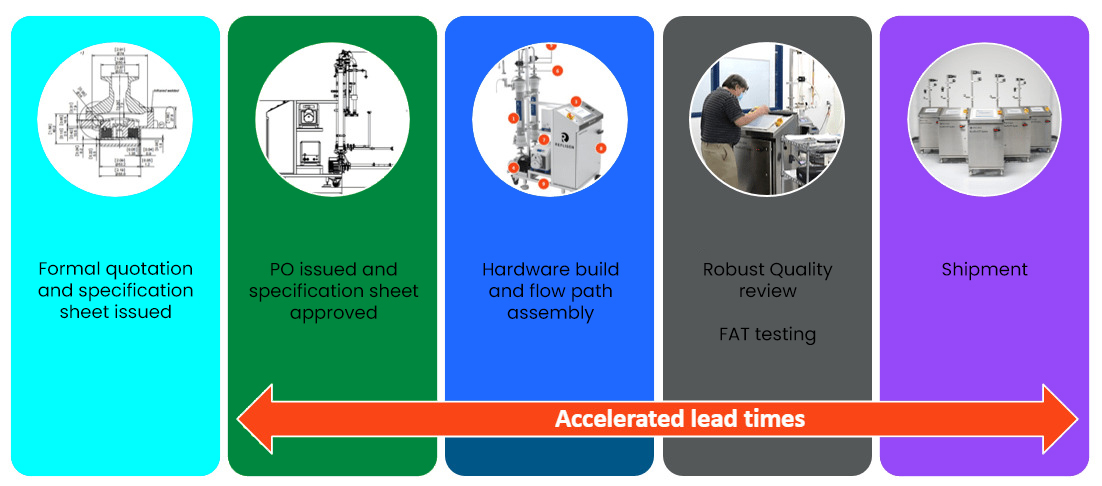

Manufacturing Centers of Excellence

Repligen develops and manufactures products for the biopharmaceutical industry under an ISO 9001 quality management system. We focus on the timely delivery of high quality, consistent and robust products, to ensure business continuity for our customers.

Repligen manufacturing sites are located in Massachusetts, California, and New Jersey in the United States and in Sweden, France, The Netherlands, Germany and Estonia.

Expert Project Management

Customer First.

Support is part of the Repligen DNA. Our goal is to provide exceptional customer experience, and to support the efficient and successful adoption and implementation of all Repligen products and services.

- Field Application Support

- Customer Service

- Field Service Engineers

XCell ATF® Lab Devices

XCell ATF® 1 Device (SU)

0.5-2 L

XCell ATF® 2 Device (SU, SS)

2-10 L

XCell ATF® 4 Device (SS)

10-50 L

Resources

Investigation of XCell ATF® Perfusion Technology for virus manufacturing process intensification at MSD Animal Health

Repligen Corporation

MSD Animal Health

July 2022

Specifications

|

|

|

||

|---|---|---|---|---|

|

XCell® ATF 1 |

XCell® ATF 2 |

XCell® ATF 4 |

||

| Typical Bioreactor size (L) | 0.5 - 2 | 2 - 10 | 10 - 50 | |

| Format | SU | SU, SS | SS | |

| Chemistry | PES | PES, PS | PES, PS | |

| Typical pore size SU | 0.2µ | 0.2µ | 0.2µ | |

| Typical pore size SS | NA | 0.2µ, 0.5µ, 50KDa | 0.2µ, 0.5µ, 50KDa | |

| Effective surface area (m2) | 0.022 | 0.13 | 0.77 | |

| Filter height (cm) | 60 | 60 | 30 | |

| Displacement volume (L) | 0.017 | 0.1 | 0.4 | |

| ATF flow range (Lpm) | 0.008 - 0.140 | 0.4 - 1.5 | 3 - 8 | |

| Typical scalable flow/fiber and filtrate rate | 12 mL/min/fiber and 4-6 LMH | |||

| Controller | XCell Lab Scale Controller |

|

||